|

|

BUILDER, HOUSEHOLDER

roof of your house. Tips for the home master

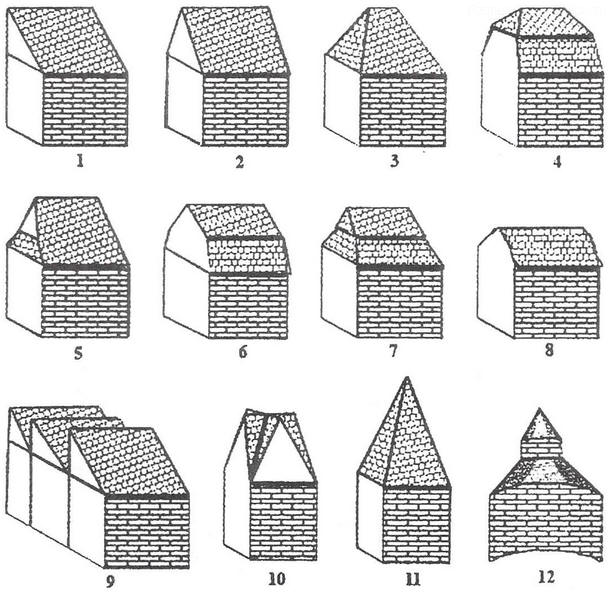

Directory / Builder, home master When the ancient man left the caves and moved to the valleys and forests, primitive buildings with a roof in the form of a canopy, built from branches and animal skins, became his dwelling. Centuries passed, people improved not only buildings, but also the roof. A Scandinavian proverb says: "The roof is the fifth façade." Modern technologies and a rich selection of building materials make this element of a residential building not only reliable, but also beautiful and light. Human fantasy tirelessly creates new roof structures. What only does not happen in the world! For example, in Germany they build roofs that are three times higher than the walls of the house itself. And look at the Chinese or Japanese pagodas: they mischievously turned up the corners of their roofs to the sky. In the West, grass coverings of buildings are very popular: it is both environmentally friendly and cool in the heat. Many craftsmen use the usable roof area for their needs by placing solar panels or a solar-heated water system there. Figure 1 shows the most typical roof shapes. Despite the wide variety of their designs, the supporting rafter base of the roof is still the same. We will talk about her. In Russia, a set of rules for the design and construction of SP 31-105-2002 is used, its eighth section is devoted to the roof.

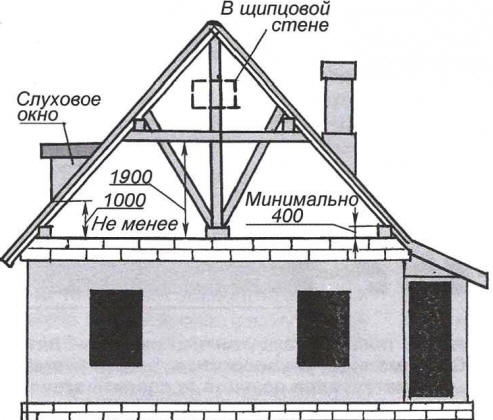

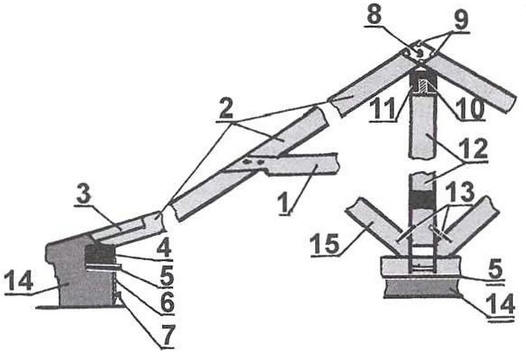

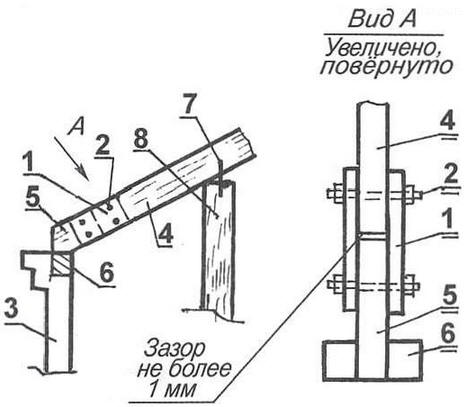

In addition, for more detailed information, you can refer to building codes and regulations (SNiP II-26-76 in part 2 of chapter 26), which refers to roofs. So, what is the support for different types of coatings? All roof parts have special names. In order not to get confused in the future, we will give a small list (Fig. 3-5). Rafters Bearing structures of a pitched roof; consist of inclined rafter legs, vertical racks and inclined struts. If necessary, they are connected below with horizontal rafter beams. In general, this is a structure that supports the roof slopes. roof truss A beam structure from a system of parallel inclined beams (rafter legs), resting with the lower end on the Mauerlat (see Fig. 6), and the upper end on the ridge beam. Mare A short board sewn with nails to the rafter leg, on which the cornice overhang of the roof rests. The horse The upper horizontal edge of a roof formed by the intersection of two roof slopes. Console Part of a beam or other structure that protrudes beyond the plane of the wall. Mauerlat (rafter beam) A timber used as a support for inclined wooden trusses and designed to distribute the load created by the roof of the structure. Located on the upper inner edge of the stone walls. Rims Bars, boards, poles, planks located across the rafters for flooring roofing material on them. Pilaster A flat vertical protrusion in the wall, processed in the form of a column (warrant) to support the roof slope. Beamer (scramble) Pieces of timber located between the carrier beam and the support posts. Designed to distribute the vertical load. Brace (bracing) A building element that connects two frame nodes, trusses, rafters. Located diagonally in a closed loop, provides structural rigidity. Rigel A horizontal element of a building structure (beam, purlin). In frames it connects racks, in frames - supports, in roofs - rafters. In the total volume of construction work on the construction of a residential building, the cost of the roof is about 18%; its qualities provide reliable protection of the building from precipitation, wind, solar radiation. Let us turn to the most common pitched roof in residential construction. The slope of the slopes depends on many factors: firstly, on the material, and secondly, on the climatic zone in which the house is located. In the northern regions, the slope should be made as steep as possible so that masses of snow do not accumulate on the roof and do not create a danger of overloading the supporting structures. And where strong winds are frequent, the roof, on the contrary, should be low so that it does not suffer from destructive gusts. In the southern regions, the roof is painted in light colors, reflecting the hot rays of the sun. As a rule, the roof of an individual house has a cold attic, and insulation is arranged along the attic floor. Dormer and ventilation windows are made in the gable (front) wall of the attic and in the roof (Fig. 2). This avoids overheating of the premises of the upper residential floor in the summer and removes moist air penetrating into the attic from the heated premises in the winter. There are attic height standards to ensure its ventilation, lighting and passage. The roof rests on a mauerlat, which must be mounted above the attic floor at least 400 mm. From the crossbar or scrum to the floor of the attic, the distance is at least 1900 mm. A fully assembled element for roof support is called a truss truss. Figure 3 clearly shows what elements it consists of, as well as the order of their attachment. The rafter legs (2) rest on the mauerlat (4) and the ridge beam (11), which, in turn, rests on a post fixed above the middle load-bearing wall of the floor and reinforced with spacers. With a large span of rafter legs, the danger of their bending is reduced due to contractions (crossbars) (1). So that the supporting truss frame does not blow away with a strong wind, the ends of the rafter legs through one are attached to the wall with a wire twist, firmly nailed to the wall with a metal crutch (6, 7). The step between the rafter legs is from 800 to 1200 mm. All wooden elements resting on concrete and stone parts must be isolated from them using roofing paper or tarred wooden beds. The structures of the floor supports depend on the width of the span of the roof truss. If the roof is gable, then you should be guided by Figure 5. If it is single-pitched, then the dimensions are maintained in accordance with Figure 4.

If the width of the roof span is less than 9 m, then hanging rafters are used. In this case, the rafter legs rest on the outer wall, and the ends are reinforced with a bar, the so-called puff. A rigid triangle is formed. You can additionally enter the top crossbar into the mount. Recently, the construction industry has mastered the production of prefabricated wooden and metal roof trusses, which save the builder from complex assembly. Moreover, the base of the trusses is made of a reinforced profile, which makes it possible to make an attic floor according to these structural elements. After the installation of the rafters is completed, the builders arrange a wooden crate, consisting of beams or boards nailed across the rafter legs. The degree of their density depends on what kind of roof is laid in the project. The heavier it is (slate, clay tiles), the denser the boardwalk. For example, with a slate roof, the distance between the boards or the beam of the battens is made no more than 490 mm, and with clay tiles - no more than 330 mm. The joining lines of the roof elements must necessarily lie on the board of the crate. In places where the slopes, cornices and along the ridges meet, the crate is built solid. From below, under the rafters, the ceiling is usually sheathed with plasterboard sheets, and the necessary hydro and thermal insulation is laid inside. If the attic turned out to be spacious, then it can be used as an attic floor or auxiliary premises. Construction companies usually include roofing services in the full construction of a residential building.

Roof truss repair If any wooden elements of the roof have become unusable, then along with the elimination of defects, it is necessary to identify the cause of their occurrence. Most often, this is a violation of the requirements for the roof, poor ventilation of the attic, poor-quality insulation and hydro-wind insulation of the under-roof space, loose locking of the attic hatch, overflows of the water heating expansion tank. When reconstructing the roof, it is recommended to disassemble it in parts in order to avoid getting wet during precipitation. For the repair of wooden structures, lumber should be used, the moisture content of which is not more than 25%. Large elements, such as rafter legs, should be treated with fire retardant and antiseptic compounds. It is necessary to carefully examine all wooden parts for damage by rot, fungus and grinder beetle. All damaged areas must be carefully removed, removed from the roof and burned. If the lesion is insignificant, then this place can be hewn and treated with an antiseptic. Then check the integrity of the insulation of wooden elements from concrete and stone structures. It is not allowed to seal the ends of wooden supports into the wall masonry. If any part is changed in the rafters, then the structure is unfastened so that the forces in the replaced elements perceive temporary structures. The rotted end of the rafter leg is removed and a new one is installed, which is attached to the remaining part with two side plates and through bolts with wide washers, and the cross-sectional area of \uXNUMXb\uXNUMXbthese plates must be no less than the cross-sectional area of \uXNUMXb\uXNUMXbthe rafter leg. The Mauerlat and the insulating lining are changed using a car jack. The sagging of the roof is eliminated only by leveling or replacing the rafter leg. You can not hem boards to it to eliminate this defect. All joints and cuts of load-bearing structures must be tightly fitted, the gap can be no more than 1 mm. It is unacceptable to leave through cracks. The developer should be aware that if he decides to change the type of roofing, then he will most likely have to compact the crate and, possibly, change the slope of the rafter legs. Author: V. Gorblyuk

Machine for thinning flowers in gardens

02.05.2024 Advanced Infrared Microscope

02.05.2024 Air trap for insects

01.05.2024

▪ Electronic innovations in service in Iraq ▪ MSP430FR5969 - high-performance microcontroller with FRAM memory

▪ section of the site Radioelectronics and electrical engineering. Article selection ▪ article I just work as a magician. Popular expression ▪ article How much fuel does one passenger plane use? Detailed answer ▪ article Luk-Tatar. Legends, cultivation, methods of application

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

See other articles Section

See other articles Section