Free technical library

Free technical library

Preparatory work before the installation of electrical wiring. Punch work. Encyclopedia of radio electronics and electrical engineering

Encyclopedia of radio electronics and electrical engineering / Electric installation work

Comments on the article

Comments on the article

At this stage, grooves are punched for hidden electrical wiring, socket (blind) holes for installing junction boxes (and, if necessary, junction boxes), boxes for switches and sockets, through holes in the walls for laying wires from room to room and through holes in the ceiling for fastening hooks for hanging ceiling lights.

Despite the apparent simplicity, this is a rather laborious operation. When choosing a method for obtaining nests and holes in concrete bases, one should pay attention not only to the brand of concrete, but also to the type of inert filler. Brick- or limestone-filled concrete can be drilled. If the filler is granite or sandstone (in slag concrete), then this is extremely difficult to do.

To obtain nests and holes, working tools equipped with hard alloy plates are used, for example, drills, crowns with a set of accessories, bolts, drills, punches. For drilling holes for dowels, drills with a diameter of 5-8 mm are used, for making passages - drills with a diameter of 20 and 25 mm, crowns with a diameter of 78 and 108 mm. Bolts can be in five sizes (from 16 to 26 mm), drills - in six sizes (from 18 to 30 mm). With concrete filled with crushed granite or pebbles (it has a high hardness), it is easiest to deal with a perforator - a manual electric percussion-rotary machine. In brick and concrete foundations, nests are punched with a mandrel of the OPKMU type with a punch. The mandrel's polyethylene cover has a locking screw to hold the punch in the mandrel. For punching sockets with a diameter of 5,8 and 7,8 mm, manual punches are used, respectively, PO-1U1 and PO-2U1, which make holes for dowels.

Instead of special mandrels with punches, you can use a piece of round steel with a diameter of 18-20 mm with a socket drilled from one end, into which the tail of the drill with a carbide tip is inserted. To keep the drill in the mandrel, on the side of it, opposite the middle of the nest, a hole is drilled, threaded and a locking screw is screwed in.

Holes and nests are drilled with an electric drill that has double insulation (the presence of double insulation is indicated by a sign on the device body).

Drills must be carbide-tipped, their size must be selected taking into account the depth of the wires. Sampling of nests in gypsum partitions and brick walls for laying wires with hidden wiring is performed by a mechanism for sampling furrows of the MVB-2MU1 type, which allows making furrows 8 mm wide and 20 mm deep. This mechanism is put into action with the help of an IE-1022A electric drill. The selection of furrows in plastered surfaces, gypsum and brick walls is carried out with furrow makers for the IE-1032 electric drill. Instead of furrow-making attachments, you can use an electric drill and a metal vulcanite circle with a diameter of 50-100 mm (Fig. 28). To ensure electrical safety, the electric drill must have double insulation, if it is not there, then the electric drill should be connected to the 220 V network only through a residual current device (AZO), for example, type RCD 010.2.OPUKHL2.

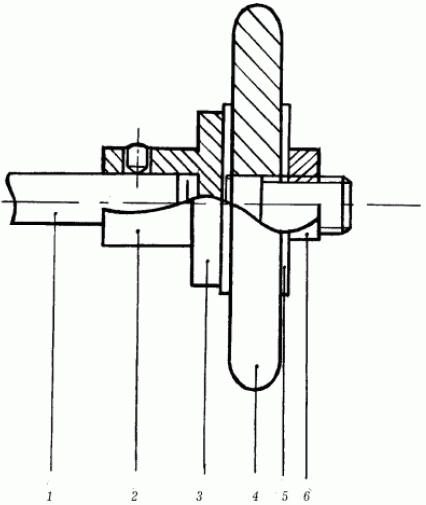

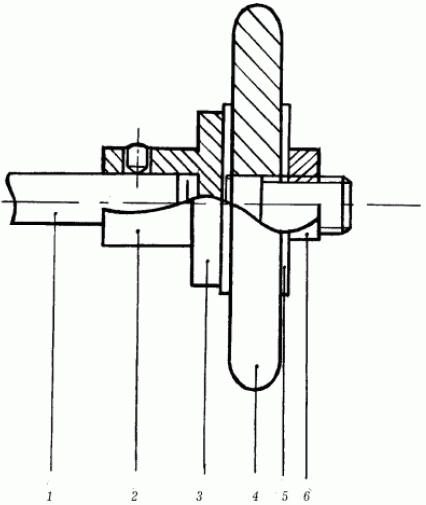

Rice. 28. Device for sampling furrows in gypsum partitions of brick walls: 1 - electric drill shaft; 2 - housing of the furrower attachment; 3 - bead; 4 - sandpaper pads; 5 - volcanic circle; 6 - nut.

In cases where the open wiring line must be protected from the effects of an aggressive environment (dampness, explosive gas mixtures, reactive gases) or from mechanical damage, the wires are laid in steel, plastic (polyethylene, polypropylene, vinyl plastic) pipes or metal flexible hoses. Their marking and cutting is carried out within the framework of the same procurement stage. The diameter of the pipes is chosen depending on the number and diameter of the wires of a particular electric line.

When preparing steel pipes, they are inspected, crumpled are rejected, bent are straightened; then they are cleaned of rust, dirt and painted (both outside and inside). Cutting is done with a hacksaw (the cut must be processed with files, otherwise the burrs can damage the wire insulation). The use of plastic pipes is possible only at an ambient temperature of not more than 60 ° C. Since plastic is easily bent, during assembly, the pipe can not be connected at the turns of the route, but pre-bent, heated to a temperature of 100-130 ° C.

Author: Korshevr N.G.

See other articles Section Electric installation work.

See other articles Section Electric installation work.

Read and write useful comments on this article.

Read and write useful comments on this article.

<< Back

Latest news of science and technology, new electronics:

Latest news of science and technology, new electronics:

A New Way to Control and Manipulate Optical Signals

05.05.2024

The modern world of science and technology is developing rapidly, and every day new methods and technologies appear that open up new prospects for us in various fields. One such innovation is the development by German scientists of a new way to control optical signals, which could lead to significant progress in the field of photonics. Recent research has allowed German scientists to create a tunable waveplate inside a fused silica waveguide. This method, based on the use of a liquid crystal layer, allows one to effectively change the polarization of light passing through a waveguide. This technological breakthrough opens up new prospects for the development of compact and efficient photonic devices capable of processing large volumes of data. The electro-optical control of polarization provided by the new method could provide the basis for a new class of integrated photonic devices. This opens up great opportunities for ... >>

Primium Seneca keyboard

05.05.2024

Keyboards are an integral part of our daily computer work. However, one of the main problems that users face is noise, especially in the case of premium models. But with the new Seneca keyboard from Norbauer & Co, that may change. Seneca is not just a keyboard, it is the result of five years of development work to create the ideal device. Every aspect of this keyboard, from acoustic properties to mechanical characteristics, has been carefully considered and balanced. One of the key features of Seneca is its silent stabilizers, which solve the noise problem common to many keyboards. In addition, the keyboard supports various key widths, making it convenient for any user. Although Seneca is not yet available for purchase, it is scheduled for release in late summer. Norbauer & Co's Seneca represents new standards in keyboard design. Her ... >>

The world's tallest astronomical observatory opened

04.05.2024

Exploring space and its mysteries is a task that attracts the attention of astronomers from all over the world. In the fresh air of the high mountains, far from city light pollution, the stars and planets reveal their secrets with greater clarity. A new page is opening in the history of astronomy with the opening of the world's highest astronomical observatory - the Atacama Observatory of the University of Tokyo. The Atacama Observatory, located at an altitude of 5640 meters above sea level, opens up new opportunities for astronomers in the study of space. This site has become the highest location for a ground-based telescope, providing researchers with a unique tool for studying infrared waves in the Universe. Although the high altitude location provides clearer skies and less interference from the atmosphere, building an observatory on a high mountain poses enormous difficulties and challenges. However, despite the difficulties, the new observatory opens up broad research prospects for astronomers. ... >>

Random news from the Archive Random news from the Archive MAX20343/MAX20344 converters

15.07.2021

Maxim Integrated has mastered the production of the new MAX20343/MAX20344 switching voltage regulators for use in compact, portable battery-powered devices. The MAX20343/MAX20344 is a fully integrated solution that combines a controller and power transistors in a single package that can drive loads up to 1A at 3,5V output.

The power section of the MAX20343/MAX20344 microcircuits is built on a non-inverting buck-boost circuit, which allows them to be used with primary energy sources, the voltage of which can be either higher or lower than the required output voltage. At the same time, special attention was paid to the functioning of the microcircuit in cases where the input voltage is approximately equal to the output: thanks to the unique transistor switching algorithm in these modes, it was possible to avoid sudden voltage fluctuations on the load and reduce the level of electromagnetic interference.

The key benefits of the MAX20343/MAX20344 are high efficiency (provided by flexible power section configuration and adaptive power switching algorithm), ultra-low internal current consumption, starting at 3,5 µA in operation and decreasing to 0,3 µA in standby mode, small levels of output voltage ripple and electromagnetic interference. The combination of these advantages makes the MAX20343/MAX20344 ideal for medical applications, such as portable photoplethysmographs, whose measurement accuracy is directly dependent on the levels of ripple and noise in the power supply circuits of the optical measurement system.

The high speed of response to transient processes, including sharp fluctuations in the input voltage, allows these microcircuits to be used to power devices with a sharply changing load, for example, wireless sensors of intelligent automated systems using LPWAN networks. In such applications, low power density primary power supplies are often used in conjunction with supercapacitors. In this case, the ability to work at an input voltage of 1,9 V allows you to maximize the installed power of the supercapacitor and increase the battery life.

Another area of application for the MAX20343/MAX20344 chips are the Truly Wireless Stereo Bluetooth headphones. With a large voltage difference between the batteries of the case and the headphones, the latter, due to a decrease in the efficiency of the integrated chargers, begin to warm up, which can cause some discomfort when using them and leads to waste of a limited amount of battery power in the case. In this case, the use of MAX20343/MAX20344 chips will reduce the voltage supplied to the headphone chargers, which will lead to less heating of their cases and more rational use of the battery power of the case.

|

Other interesting news:

Other interesting news:

▪ Seventeenth moon of Jupiter

▪ Precision temperature sensors TE Connectivity G-NIMO-00x

▪ Smart scales determine the speed of propagation of the pulse wave

▪ TI Hercules RM57Lx and TMS570LCx microcontrollers

▪ Rare earths from the ocean floor

News feed of science and technology, new electronics

News feed of science and technology, new electronics

Interesting materials of the Free Technical Library:

Interesting materials of the Free Technical Library:

▪ site section Regulators of current, voltage, power. Article selection

▪ article Orientation in local subjects. Fundamentals of safe life

▪ article What is the first cosmic velocity? Detailed answer

▪ Article Executive Director. Job description

▪ article Compositions of casein paints. Simple recipes and tips

▪ article Cable lines up to 220 kV. Feeding devices and signaling of oil pressure of cable oil-filled lines. Encyclopedia of radio electronics and electrical engineering

Leave your comment on this article:

Leave your comment on this article:

All languages of this page

All languages of this page

Home page | Library | Articles | Website map | Site Reviews

www.diagram.com.ua

2000-2024

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

Leave your comment on this article:

Leave your comment on this article: