|

|

ENCYCLOPEDIA OF RADIO ELECTRONICS AND ELECTRICAL ENGINEERING Improvement of the octane corrector. Encyclopedia of radio electronics and electrical engineering

Encyclopedia of radio electronics and electrical engineering / Automobile. Ignition This article is devoted to further improvement of the octane corrector design, popular with motorists. The proposed additional device significantly increases the efficiency of its application. The electronic octane corrector by V. Sidorchuk [1], modified by E. Adigamov [2], is certainly simple, reliable in operation and has excellent compatibility with various ignition systems. Unfortunately, for him, like for other similar devices, the delay time of the ignition pulses depends only on the position of the ignition timing knob (IDO). This means that the set angle is optimal, strictly speaking, only for one value of the crankshaft speed (or vehicle speed in a particular gear). It is known that the car engine is equipped with centrifugal and vacuum automatic devices that correct the UOZ depending on the crankshaft speed and engine load, as well as a mechanical adjusting octane corrector. The actual SPD at each moment is determined by the total action of all these devices, and when using an electronic octane corrector, one more significant term is added to the result. UOZ provided by an electronic octane-corrector [2], At N = 750 min -1, the delay time will correspond to 4,5 deg., and at 3000 min -1 - 18 deg. angle of rotation of the crankshaft. At 750 min -1, the resulting UOP is +10,5 degrees, at 1500 min -1 - +6 degrees, and at 3000 min -1 - minus 3 degrees. Moreover, at the time of operation of the ignition delay switch-off unit (N = 3000 min -1 ), the UOS will change dramatically immediately by 18 degrees. This example is illustrated in Fig. 1 dependence graph of UOP (

At the same time, it is possible, by a simple modification, to eliminate this drawback and turn the octane corrector into a device that allows maintaining the required UOZ over a wide range of crankshaft speeds. On fig. Figure 2 shows a schematic diagram of the unit that needs to be supplemented with an octane corrector [2].

The node works as follows. The low-level pulses taken from the output of the inverter DD1.1, through the differentiating circuit C1R1VD1, are fed to the input of the timer DA1, which is connected according to the one-shot circuit. The output rectangular pulses of a single vibrator have constant duration and amplitude, and the frequency is proportional to the engine speed. From the voltage divider R3, these pulses are fed to the integrating circuit R4C4, which converts them into a constant voltage, which is directly proportional to the crankshaft speed. This voltage charges the timing capacitor C2 of the octane corrector. Thus, with an increase in the crankshaft speed, the charging time of the timing capacitor is proportionally reduced to the switching voltage of the logic element DD1.4 and, accordingly, the delay time introduced by the electronic octane corrector is reduced. The required dependence of the change in the charging voltage on the frequency is provided by setting the initial voltage on the capacitor C4, taken from the engine resistor R3, as well as adjusting the duration of the output pulses of the single vibrator resistor R2. In addition, in the octane corrector [2], the resistance of the resistor R4 must be increased from 6,8 to 22 kOhm, and the capacitance of the capacitor C2 must be reduced from 0,05 to 0,033 μF. The output of the resistor R6 (X1) left according to the scheme is disconnected from the positive wire and connected to the common point of the capacitor C4 and the resistor R4 of the added node. The supply voltage to the octane corrector is supplied from the parametric stabilizer R5VD2 of the additional node. The octane-corrector with the indicated modifications provides the adjustment of the ignition timing delay, equivalent to a change in the SPD within 0 ... -10 deg. relative to the value set by the mechanical octane corrector. The characteristic of the device operation under the same initial conditions as in the above example is shown in Fig. 1 curve 3. At the maximum delay time of the ignition moment, the error in maintaining the UOZ in the range of the crankshaft speed of 1200 ... 3000 min -1 is practically absent, at 900 min -1 it does not exceed 0,5 degrees, and in the idle mode - no more than 1,5 ...2 deg. The delay does not depend on the change in the voltage of the car's on-board network within 9 ... 15 V. The modified octane corrector retains the ability to provide sparking when the supply voltage is reduced to 6 V. If you want to expand the regulation range of the UOZ, it is recommended to increase the resistance of the variable resistor R6. The proposed device differs from those described in [3; 4], circuit simplicity, reliability of operation, as well as the ability to interface with almost any ignition system. The additional node used fixed resistors MLT, trimming resistors R2, R3 - CP5-2, capacitors C1-C3 - KM-5, KM-6, C4 - K52-1B. The zener diode VD2 must be selected with a stabilization voltage of 7,5 ... 7,7 V. The parts of the unit are placed on a printed circuit board made of foil fiberglass with a thickness of 1 ... 1,5 mm. The board drawing is shown in fig. 3.

The node board is attached to the octane corrector board. It is best to mount the entire device assembly in a separate, durable casing, which is fixed near the ignition unit. Care must be taken to protect the octane corrector from moisture and dust. It can be made in the form of an easily removable unit installed in the passenger compartment, for example, on the side wall below, to the left of the driver's seat. In this case, when the octane corrector is removed, the ignition circuit will be open, which will at least make it very difficult for an unauthorized person to start the engine. Thus, the octane corrector will additionally perform the function of an anti-theft device. For the same purpose, it is advisable to use an adjusting variable resistor SP3-30 (R6) with a switch that opens the electrical circuit of this resistor. To set up the device, you will need a power supply with a voltage of 12 ... 15 V, any low-frequency oscilloscope, voltmeter and pulse generator, which can be performed as indicated in [1]. First, the input circuit of the DA1 timer is temporarily turned off, and the slider of the resistor R3 is set to the lower (according to the diagram) position. Pulses with a frequency of 40 Hz are fed to the input of the octane corrector and, by connecting the oscilloscope to its output, the voltage across the capacitor C3 is gradually increased by resistor R4 until output pulses appear. Then the input circuit of the timer is restored, the oscilloscope is connected to its output 3 and the duration of the output pulses of the one-shot equal to 2 ... 7,5 ms is set with resistor R8. The oscilloscope is connected again, switched to external synchronization mode with a waiting sweep triggered by input pulses (it is best to use the simplest two-channel switch), the output pulse delay time of 6 ms is set to the output of the octane corrector and resistor R1. The generator frequency is increased to 80 Hz and the delay time is set to 2 ms with resistor R0,5. After checking after that the duration of the pulse delay at a frequency of 40 Hz, the adjustment is repeated, if necessary, until the duration at a frequency of 80 Hz is exactly half that at a frequency of 40 Hz. It should be borne in mind that in order to ensure stable operation of the single vibrator up to the frequency of operation of the ignition delay switch-off unit (100 Hz), the duration of its output pulses should not exceed 9,5 ms. In fact, in a well-established device, it does not exceed 8 ms. Then the generator frequency is reduced to 20 Hz and the input pulse delay obtained at this frequency is measured. If it is at least 1,6 ... 1,7 ms, then the adjustment is completed, the adjusting screws of the tuning resistors are fixed with paint, and the board, on the side of the printed conductors, is covered with nitro-lacquer. Otherwise, the resistor R3 slightly reduces the initial voltage across the capacitor C4, increasing the delay time to the specified value, after which they check and, if necessary, adjust again at a frequency of 40 and 80 Hz. One should not strive for a strict linearity of the frequency dependence of the delay time in the section below 40 ... 30 Hz, since this requires a significant reduction in the initial voltage on the capacitor C4, which can lead to the disappearance of ignition pulses at the lowest crankshaft speeds or unstable operation of the ignition system at starting the engine. A small residual error, expressed as a slight decrease in the ignition delay time in the initial section (see curve 3 in Fig. 1), has a rather positive effect than a negative one, since (motorists know this well) at low speeds the engine runs more stable at a slightly earlier ignition. It is possible to adjust the device with quite acceptable accuracy without an oscilloscope. They do it like this. First, the functionality of the additional node is checked. To do this, the engines of the resistors R2 and R3 are set to the middle position, a voltmeter is connected to the capacitor C4, the device is powered on and pulses with a frequency of 20 ... 80 Hz are fed to the input of the octane corrector. Rotating the slider of the resistor R2, make sure that the voltmeter readings change. Then the slider of the resistor R2 is returned to the middle position, and the resistor R6 of the octane corrector is transferred to the position of maximum resistance. The pulse generator is turned off, and a voltage of 3 V is set on the capacitor C4 with resistor R3,7. Pulses with a frequency of 80 Hz are fed to the input of the octane corrector and a voltage of 2 V is set on this capacitor with resistor R5,7. In conclusion, take readings of the voltmeter at three frequencies - 0, 20 and 40 Hz. They should be 3,7, 4,2 and 4,7 V, respectively. If necessary, repeat the adjustment. Connecting the modified octane corrector to the on-board system of cars of various brands has no special features compared to that described in [2, 5, 6]. After installing the octane corrector on the car, starting and warming up the engine, the engine of the resistor R6 is moved to the middle position and the optimal UOZ is set with a mechanical octane corrector, as indicated in the car's operating instructions, i.e., they achieve a slight, short-term detonation of the engine when pressed sharply on the accelerator pedal while the car is moving in direct gear at a speed of 30 ... 40 km / h. This completes all adjustments. A three-year operation of the octane corrector modified by the author on a GAZ-2410 car equipped with an ignition unit 1302.3734-01 with a magnetoelectric sensor showed a noticeable improvement in the driving performance of the car. Literature

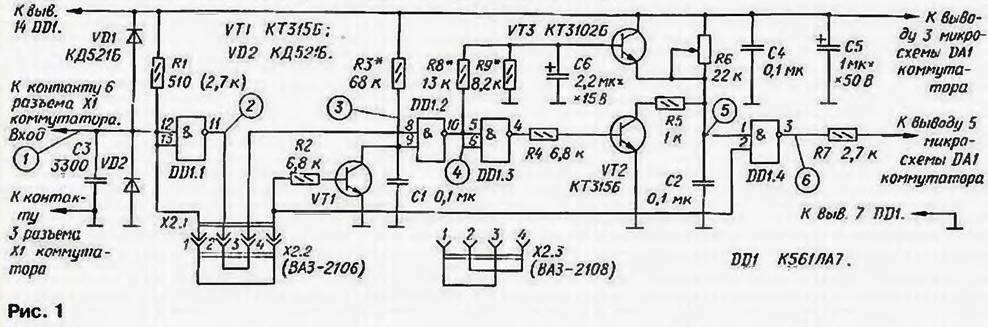

Author: K. Kupriyanov, St. Petersburg Generally speaking, changing the set ignition timing should be considered as a temporary and forced measure, in particular, if necessary, use gasoline with an octane number that does not correspond to the passport characteristics of the car engine. At present, when the quality of the fuel that we fill in the tank of our car has become, to put it mildly, unpredictable, such a device as an electronic octane corrector is simply necessary. As quite rightly noted in the article by K. Kupriyanov, when the octane corrector described in [1] is put into operation. there is a time-constant delay in the moment of ignition, proportional in angular terms to an increase in the engine crankshaft speed, followed by an abrupt increase in the angle of ignition. Although in practice this phenomenon is almost imperceptible, the internal reserves of the source device make it possible to partially eliminate the mentioned delay. To do this, it is enough to introduce the transistor VT2, resistors R3 into the device [8]. R9 and capacitor C6 (see diagram in Fig. 1). The operation algorithm of the octane corrector is qualitatively illustrated by the graphs shown in fig. 2. The opening moments of the breaker contacts correspond to positive voltage drops - from low to high - at the input of the octane corrector (diagram 1). At these moments, the capacitor C1 is rapidly discharged almost to zero through the opening transistor VT1 (diagram 3). The capacitor is charged relatively slowly through the resistor R3.

As soon as the voltage on the charging capacitor C1 reaches the switching threshold of the logic element DD1.2. it goes from a single state to a zero state (diagram 4), and DD1.3 - to a single state. The transistor VT2 that opens at this moment quickly discharges the capacitor C2 (Fig. 5) to a level practically determined by the voltage at the base of the transistor VT3. Since the switching delay of the DD1.2 element does not depend on the rotational speed, the average voltage at its output increases with increasing frequency. Capacitor C6 averages this voltage. The subsequent charging of the capacitor C2 through the resistor R6 starts exactly from the specified level at the moment the transistor VT2 closes. The lower the initial level, the longer the capacitor will charge until the element DD1.4 is switched, which means that the spark delay is longer (Fig. 6). The characteristic of the OZ angle obtained in this case is shown in fig. 3, similar to Fig. 1 in the article by K. Kupriyanov, in the form of curve 4. Under the same initial conditions (tset = 1 ms at N = 1500 min-1), the control error in the most frequently used interval of the engine crankshaft speed from 1200 to 3000 min-1 when driving 3 does not exceed XNUMX deg.

It should be noted that the operation of this version of the octane corrector depends significantly on the duty cycle of the input pulses. Therefore, to establish it, it is recommended to assemble the pulse shaper according to the scheme in Fig. 4. As you know, the pulses from the Hall sensor of the VAZ-2108 car and its modifications have a duty cycle equal to 3, and the angle of the closed state of the contacts φзс of the contact breaker of VAZ cars is 55 degrees, i.e., the duty cycle of the pulses from the "six" breaker Q = 90/55= 1,63.

In order to be able to use the same pulse shaper to establish octane correctors for different car models with only a small adjustment of the duty cycle, the duty cycle is recalculated for the contact ignition system, taking into account inversion: Qinv = 90 / (90 - φss). or for VAZ-2106 Qinv = 90/(90 - 55)=2.57. By selecting the number of diodes of the shaper and the sinusoidal voltage of the signal generator, the required duty cycle of the pulses at the input of the octane corrector is obtained. In my practical version, four diodes were needed to obtain a duty cycle of 3 with a generator signal amplitude of 5.7 V. In addition to those indicated, diodes of the D220 series are suitable for the shaper. D223, KD521, KD522 and KT315 transistor with any letter index. It is possible to apply a pulse shaper of a given duty cycle according to another scheme. The corrector for the VAZ-2108 car (the jumper X2.3 is inserted in Fig. 1) is adjusted as follows. Instead of the divider R8R9, temporarily connect any variable resistor of group A with a resistance of 22 kOhm (the engine to the base of the transistor VT3). First, the resistor slider is set to the extreme position in which the base of the transistor is "grounded". A shaper is connected to the input of the corrector, and an oscilloscope is connected to the output. The power of the corrector is turned on and the generator frequency is set to 120 Hz with the duty cycle of the output pulses of the shaper equal to 3. Resistor R3 is selected to turn off the delay at this frequency. Then the generator frequency is reduced to 50 Hz and, by moving the slider of the resistor R6 alternately to both extreme positions, the maximum ignition delay time introduced by the octane corrector is determined (in our case, 1 ms). The frequency of the generator is increased to 100 Hz and the position of the temporary variable resistor engine is found in which the maximum ignition timing delay is set by resistor R6. equal to half the maximum - 0.5 ms. Now it is advisable to take a graph of the dependence of the delay time of the ignition moment on the frequency of the generator with the position of the engine of the temporary variable resistor found. Recalculate the engine shaft speed in min-1: N = 30f. where f is the generator frequency. Hz. OZ angle φoz = 6N t, where t is the delay time, ms. The resulting angle φres oz = 15 - φoz (see table) is plotted on the graph in fig. 3.

The shape of the resulting graph should not differ much from curve 4, although the numerical values may be different depending on the maximum delay time. If necessary, repeat the adjustment operation. Upon completion of the adjustment, the temporary variable resistor is turned off and, having measured the resistance of its shoulders, the fixed resistors with the values closest to the measured ones are soldered. It should be noted that the regulation characteristic can be significantly changed by varying the values of the resistor R3 (delay off frequency), divider R8R9 and capacitor C6. The initial conditions of the described regulation are chosen for comparison with the option chosen by K. Kupriyanov: N = 1500 min-1, t = 1 ms, φmok = +15 deg. (φmok - the angle set by the mechanical octane corrector). For use on a VAZ-2106 car, the octane corrector is adjusted in the same way (with a jumper X2.3), but the pulses from the shaper must have a duty cycle of 2.57. Before installing the corrector on the car, the X2.3 jumper is changed to X2.2. To finalize the octane corrector [2], its board is removed from the switch 3620.3734 and the transistor VT3 and capacitor C6 are soldered by hanging mounting so that the board can be installed in the old place. The selected resistors R8 and R9 are soldered to the board. Transistor V13 and capacitor C6 should be fixed with glue "Moment" or similar. Instead of KT3102B, any transistor of this series will do. Capacitor C6 - K53-4 or any tantalum or oxide semiconductor, suitable in size and rating. Literature

Author: E.Adigamov, Tashkent, Uzbekistan

Air trap for insects

01.05.2024 The threat of space debris to the Earth's magnetic field

01.05.2024 Solidification of bulk substances

30.04.2024

▪ Short Throw Projector LG PH450UG-GL ▪ Organic molecules found on Mars ▪ Cooler Thermaltake ToughAir 510 ▪ Smart portable storage for potatoes and onions

▪ section of the site Note to the student. Article selection ▪ article Rippers for tillage. Tips for the home master ▪ article Why did you have to import African beetles to Australia? Detailed answer ▪ article Plant Management Specialist. Standard instruction on labor protection ▪ article Disappearing coin. Focus secret

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

oz.ok=6Nt, where N - engine crankshaft speed, min -1 ; t is the ignition timing delay introduced by the electronic octane corrector, s. Suppose that the initial setting of the mechanical octane corrector corresponds to +15 deg. and at N = 1500 min -1, the optimal ignition timing delay, set by the electronic octane corrector, is 1 ms, which corresponds to 9 deg. angle of rotation of the crankshaft.

oz.ok=6Nt, where N - engine crankshaft speed, min -1 ; t is the ignition timing delay introduced by the electronic octane corrector, s. Suppose that the initial setting of the mechanical octane corrector corresponds to +15 deg. and at N = 1500 min -1, the optimal ignition timing delay, set by the electronic octane corrector, is 1 ms, which corresponds to 9 deg. angle of rotation of the crankshaft. ) on the engine speed. The dashed line 1 shows the required dependence, and the solid broken line 2 shows the actually obtained one. It is obvious that this octane-corrector is capable of optimizing the operation of the engine in terms of the ignition timing only when the car is moving for a long time at a constant speed.

) on the engine speed. The dashed line 1 shows the required dependence, and the solid broken line 2 shows the actually obtained one. It is obvious that this octane-corrector is capable of optimizing the operation of the engine in terms of the ignition timing only when the car is moving for a long time at a constant speed.

Leave your comment on this article:

Leave your comment on this article: