|

|

TOOLS AND MECHANISMS FOR AGRICULTURE

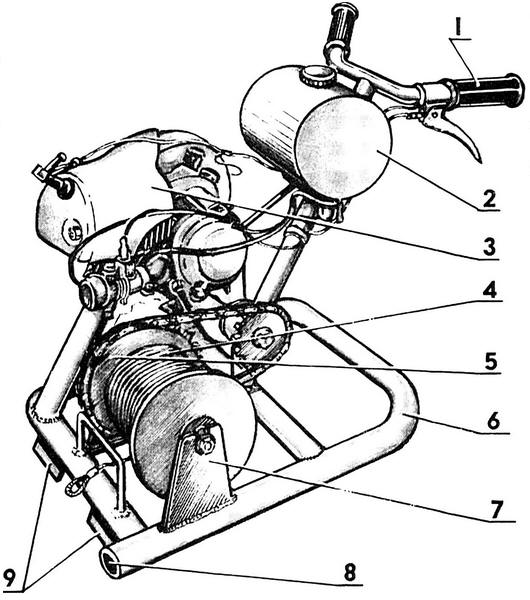

Fixed walk-behind tractor. Drawing, description

Directory / Tools and mechanisms for agriculture In our opinion, it is quite difficult to cultivate small land plots with traditional small-sized motor vehicles. Therefore, we have chosen a different technological scheme, which consists in the following: the power plant stands at one end of the section, and the working body moves from the opposite edge of the section towards the power unit. The operation itself can have two options: one move is working, the reverse is idle; in the presence of a system of blocks - both strokes are working. The main advantages of the walk-behind tractor created in our student design bureau are that it fits quite freely in the trunk of a car, and its weight is minimal; it is easy to manufacture and available in materials. The design makes it easy to dismantle the engine, which can be used in other installations. The advantage of our motor unit can be called its great versatility. And not only in tillage, although it is applicable for plowing, harrowing, cultivation, and even for laying shallow canals. The range of work performed can be greatly expanded: this includes the movement of goods, the cleaning of agricultural premises, the mechanization of construction operations, and much more. The basis of the walk-behind tractor is the VP-150 engine from the Vyatka scooter with forced cooling with a power of 4,4 kW (6 hp). It is mounted on a frame made of thin-walled pipes. To lighten the weight, the design of the frame of the power unit was solved so that it simultaneously serves as a supporting element, and an exhaust pipe, and a silencer: the exhaust gases are divided into two streams, pass along a small and large contour, then converge at a right angle. This greatly reduces the output noise level. The frame heated by the exhaust gases is cooled by the soil.

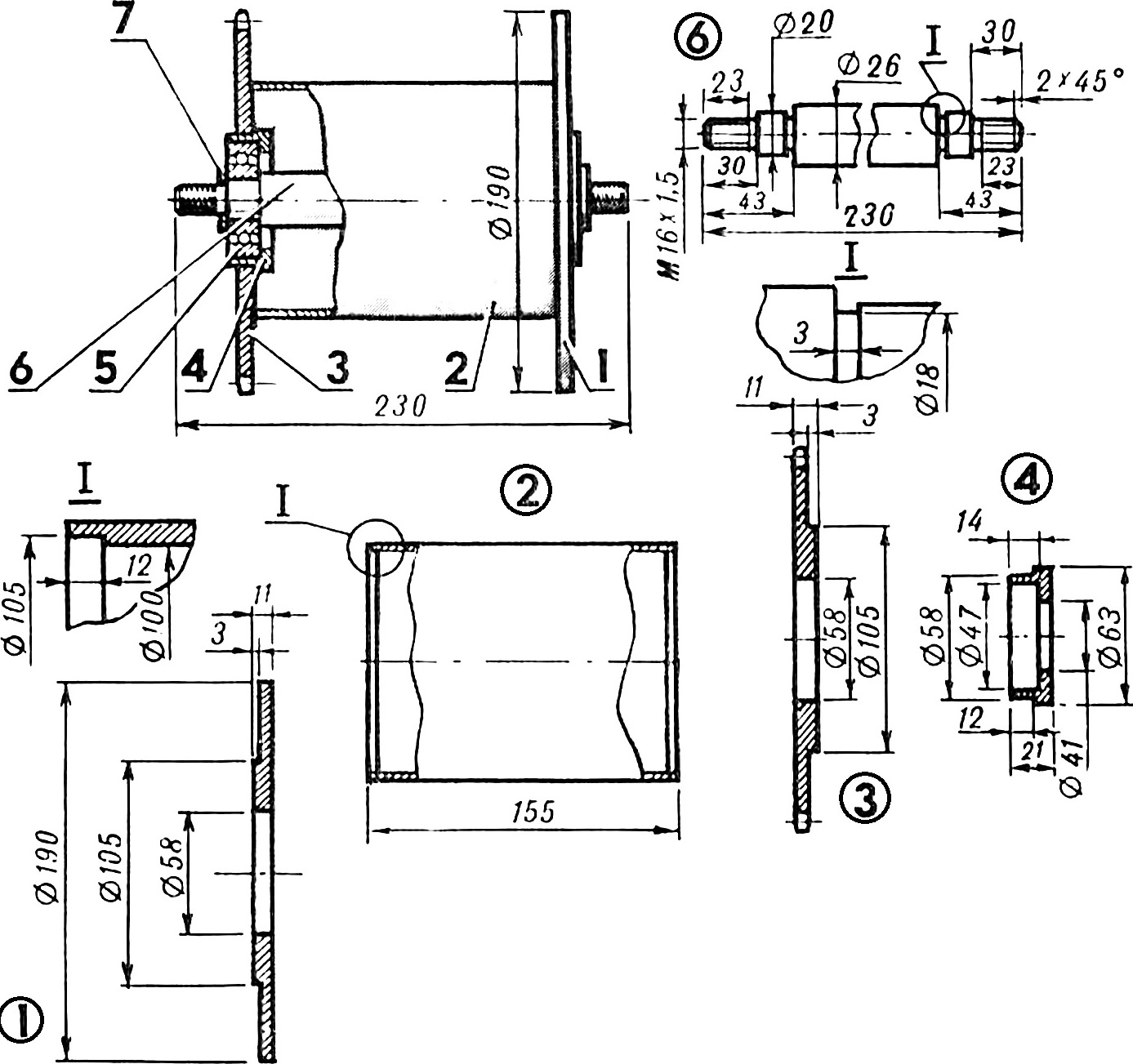

To the left of the engine, from the side of its output shaft, on two plate brackets welded to the frame, a winch drum made of a large-diameter steel pipe is installed. The torque from the engine is transmitted to its sprocket through a chain drive (pr. - 12,7-1800-2 GOST 10947-64). The cable is wound at one end on a drum, and the other end is attached to the working body - for example, a plow. If it is necessary to direct traction forces at an angle to the axis of the drum, the cable is passed through a guide bracket welded in the front of the frame, near the exhaust port.

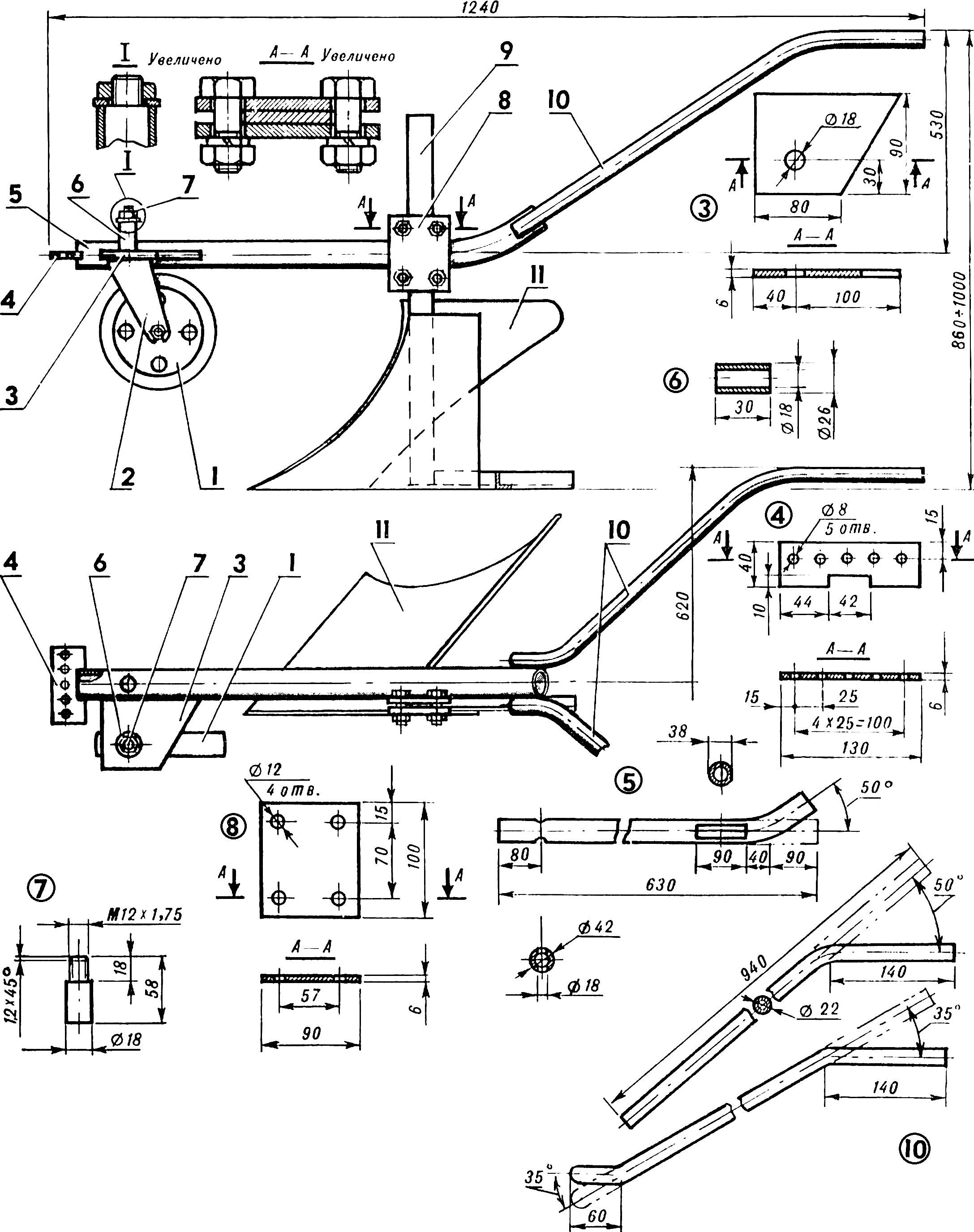

From below, steel plates are welded to the frame - lugs, which allow you to firmly fix the position of the winch when processing light and medium soils or moving small loads. For plowing virgin lands or with other increased loads, the lugs should be increased in height to at least 150 mm. Plow A replaceable working body for plowing the soil is a share plow. Its design is similar to that of a horse. The body of the plow is rigidly welded to the tine, the tine shield is also welded here, as well as the field board, which compensates for lateral reactions that occur during plowing and prevents the plow from moving to the side. The board is made of a steel equal-shelf corner 25X25 mm. The body stand is a steel strip with dimensions of 45x12x450 mm. Dump - from a steel sheet 3 mm thick.

The plow through the rack is attached with four bolts to the supporting frame, made of a pipe with an outer diameter of 42 mm. In the front part, the frame has an adjusting bar designed to connect the plow frame to the power unit through a steel cable. Below there is a bracket for fastening the fork of the support wheel. Tests have shown that, in addition to the correct implementation of all structural elements, precise adjustment of the plow is also important for successful tillage. Before starting work, it is necessary to adjust - set - the plow body to the specified plowing depth. The adjustment is carried out by changing the level of fastening of the plow body rack, and hence the position in relation to the support wheel. The greatest plowing depth that can be achieved is 22 cm. For a minimum penetration into the soil - say, when removing a surface sod layer 4-5 cm thick - another adjustment is provided. It is carried out by raising or lowering the support wheel relative to the bracket.

The principle of operation of the installation In both options - in one direction or both - two people are employed during work: one controls the power unit, the second - the working body. During plowing, the cable, winding around the drum, drags the plow through the entire area, followed by one of the workers. When the furrow is completed, the drum switches to idling (free) running, making it possible to unwind the cable - the plow is pulled to the beginning of the section for the passage of the next furrow. And so on until the end of plowing. For other types of work - when moving goods or materials, etc. - the sequence of actions with a drum and a cable is similar. It is interesting that the scheme and method of using the motor unit that we have chosen open up unexpected possibilities for its application. For example, for greenhouses. Compared to any other mechanisms with internal combustion engines, only ours allows us to avoid gas pollution in an enclosed space: while the working body is working inside the greenhouse, the motor unit, and, consequently, the exhaust gases are outside the premises. There is another winning factor - compliance with agrotechnical requirements, since a walk-behind tractor spaced in this way, which does not have a running gear, does not have a compacting effect on the soil. The motor unit turned out to be economical in terms of fuel consumption: for 0,01 ha - only 300 g of gasoline, and quite satisfactory in terms of productivity - 0,03 ha per hour. Author: G.Martynova

▪ hay lift

Machine for thinning flowers in gardens

02.05.2024 Advanced Infrared Microscope

02.05.2024 Air trap for insects

01.05.2024

▪ Smartphone charges in 10 minutes and lasts all day ▪ Topological phonons discovered in graphene ▪ Oukitel K10000 Pro smartphone with 10100 mAh battery

▪ section of the site Car. Article selection ▪ article Stones will cry out. Popular expression ▪ article Who got the first antibiotic? Detailed answer ▪ article Working with a thread-cutting tool. Standard instruction on labor protection ▪ article Telephone line controller. Encyclopedia of radio electronics and electrical engineering

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

See other articles Section

See other articles Section