|

|

HISTORY OF TECHNOLOGY, TECHNOLOGY, OBJECTS AROUND US

Typography. History of invention and production

Directory / The history of technology, technology, objects around us Typography is the process of creating printed matter. The term is usually used in a historical context. The idea of printing books, most likely, was given by stamps. Already in the XNUMXth-XNUMXth centuries, fabric with embossed decorations was being produced in Europe. When printing many repeating figures, stamps were used here. Medieval scribes in the thirteenth century also resorted to initial stamps (large, decorated letters placed at the beginning of a paragraph). The reason for this is understandable - if the text was written relatively quickly, then it took a lot of time to draw large initials. It was very convenient for the scribe to resort to a stamp, especially since in large manuscripts the same miniatures were repeated several times.

Prints were widely used in the manufacture of playing cards and cheap paintings (in particular, with images of saints). These engravings at first were only pictures, but then they began to be accompanied by several lines of text. From engravings there was only a step to the production of books. Apparently, the evolution here was the same. At first, only pictures were printed from the boards, and the text was written by hand. Then we moved on to cutting on the board (in reverse) and text explaining the drawing. In the future, it came to cutting out one text without illustrations. The first books printed in this way were small in size (we would call them pamphlets) and aimed at a poor buyer who did not have enough money to buy a real book. However, the circulation of such cheap editions was apparently large enough to justify the initial cost of cutting out the text on the boards. Among the first printed books was, for example, the "Bible of the Poor", containing several dozen sheets from the Old and New Testaments with pictures. Or "The Mirror of Human Salvation" with engravings depicting the fall of Adam and Eve, as well as some excerpts from the New Testament relating to the salvation of the soul. The third book, which had great popularity, is The Life and Passion of Christ. Along with these soul-saving writings, small educational books were popular: the Latin grammar of Elius Donatus, the grammar of Alexander Gallus and others.

The technique of making all these first works of printing was as follows. A rectangular plate of hard wood - walnut, pear or palm tree - about 2 cm thick was taken. After careful grinding and checking the correctness of the plane, a picture and text drawn on paper were drawn or pasted on it, similar to a handwritten one. At first, they drew with rough strokes - to facilitate the work, - later the technique improved, and the drawings began to come out more beautiful and elegant. Then, with sharp at the end and hard knives, all those parts that are not needed were cut deep into. As a result of this work, a convex drawing was obtained, lying all on the same plane, which remained to be smeared with paint (it was a mixture of soot with vegetable oil, for example, drying oil). The paint was applied with a tampon made of leather or strong, dense material stuffed with wool. A damp (so that the paint sticks better) sheet of paper was applied to the surface covered with paint. When the sheet took the entire design from the wooden block, it was carefully removed and hung up to dry. Then the board was again smeared with paint, and the process was repeated. At first they printed only on one side of the sheet. Then the technique improved, and both sides began to be used. The cheapness of new books created a steady demand for them, and this led to the fact that more artisans began to turn to printing. It is obvious that carving the text on the board was a laborious and painstaking undertaking. In addition, each board could only be used to print one particular book. Many craftsmen who were engaged in this difficult task probably had an idea: is it possible to speed up and simplify the printing process? Meanwhile, there was only one way to facilitate the work - the creation of movable letters that could serve for many years for the typesetting of completely different books. This idea was first brought to life by Johannes Gutenberg. He was born in Mainz and descended from the old noble family of Gonzfleisch. In 1420, Johann left Mainz, became a craftsman and adopted his mother's surname, Gutenberg. Around 1440, while living in Strasbourg, Gutenberg made his first printing press. In 1448 he returned to his native Mainz and devoted himself entirely to printing. He died in 1468. Gutenberg himself carefully concealed the essence of his invention, so the way in which he came to him can only be restored tentatively. There are reports that the first Gutenberg set was made of wood. They assure that at the beginning of the XNUMXth century they saw the remains of his first wooden type. Moreover, he made a hole in the body of each letter and tied the typed lines with a rope threaded through the holes. However, wood is not a suitable material for cutting individual small letters. In addition, it swells, dries up - and individual words turn out to be unequal in height and width. It interfered with printing. Trying to overcome this shortcoming, Gutenberg, apparently, began to carve letters from soft metal - lead or tin. Obviously, soon (if not immediately) the idea came that the letters can be cast - it will be both faster and easier. In the end, the process of manufacturing letters took the following form: the punches (exact models) of all used letters were cut out of hard metal (iron) in a mirror form. Then, by hitting them with a hammer, they received prints of letters on a copper plate (matrix). In this form, the number of letters that was needed was cast. Such letters could be used repeatedly, and for printing a variety of books. The cast letters were typed into a ruler with sides (workbench), which was a finished line.

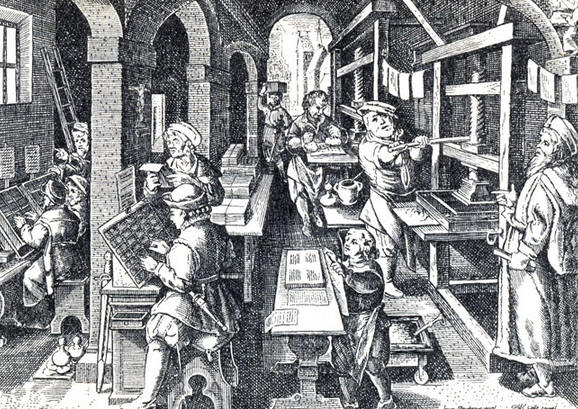

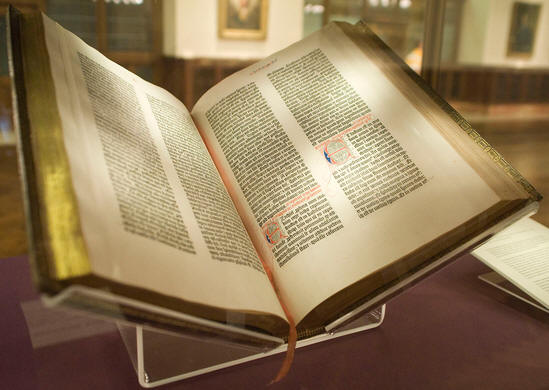

The first books of Gutenberg were the calendars and grammar of Donat (in total, he published 13 such editions). But in 1455, he ventured on a more difficult task - he published the first printed Bible with a total volume of 1286 pages (3400000 printed characters). In this edition, only the main text was typed in ink. Capital letters and drawings were drawn by hand by the artist. The method of printing discovered by Gutenberg remained virtually unchanged until the end of the 1500th century. Rarely has a discovery come in handy like the invention of the printing press. The extent to which printing corresponded to the urgent needs of mankind was shown already in the first years after the discovery of the secret of Gutenberg. Hundreds of printing houses, one after another, appeared in different cities of Europe. By 30, up to XNUMX different book titles had been published throughout Europe. Trying to make their publications more attractive, the masters supplied their books with illustrations - first in black and white, and then in color (Gutenberg himself printed books without illustrations), decorated them with beautiful title pages. In 1516, the Venetian artist Hugo da Carpi perfected the way of printing color illustrations. He decomposed the picture into several tones (usually 3-4), for each tone he made a separate board and cut out on it only those places that should have been printed on paper with these colors. First, places of one color were printed on a sheet, then another. Hugo da Carpi himself was an excellent copyist and printed in this way copies of many paintings, mainly Raphael. The texts were printed in the following way. First, the typesetter typed text from lead letters. The lines, as already mentioned, were special rulers - workbenches. They were an oblong box, open at the top and one side. When one row of the required length was typed, the typesetter aligned the line with the help of a conclusion - reduced or increased the spaces between words by removing or inserting spaces - thin pieces of type-cast metal without letters, which had a certain width. After filling the workbench, it was installed on a typesetting board. When the set of the page was over, the board was taken into a frame so that the letters would not crumble.

The printing press was a massive structure, attached with bars to the floor and ceiling. Its main part was a press with a lever, under which there was a flat table - a thaler. This thaler was designed in such a way that it could move out from under the press. A set of two or more pages (up to 32) was put on the thaler, how many of them fit, depending on the size. All convex parts of the set were smeared with paint. To prevent the paper from slipping off the set during printing, a special device was used - a deckle equipped with two or three points (graphs). It was attached to the front of the taler on hinges. Before starting printing, the master took several sheets of paper (10-20), carefully aligned them along the edges and strung them on graphics. From above, these sheets were covered with a frame (racket), which was also hinged to the deckle. The raskette covered the margins of the paper and the middle of the sheet, that is, all the parts that were supposed to remain clean. After that, the deckle was lowered onto the set, so that the bottom sheet was pressed tightly against the set. The thaler was moved under the press and, with the help of a lever, the pian (top board) was pressed against the deckle. Then the press was raised, the entire apparatus with paper was pulled out, the rack was raised and the printed sheet was removed from the graphs. In order to get the best print, the paper was lightly moistened with water. Therefore, the finished sheets were dried on a rope. After drying, an impression was made on the other side of the sheet. Then the sheets went to the binder. Author: Ryzhov K.V.

Artificial leather for touch emulation

15.04.2024 Petgugu Global cat litter

15.04.2024 The attractiveness of caring men

14.04.2024

▪ Developed paper that turns heat into electricity ▪ Finally deciphered the woman ▪ Transparent and silent robotic eel developed ▪ Garmin Quantix 5 marine smart watch

▪ section of the site Experiments in chemistry. Article selection ▪ article Faith moves mountains. Popular expression ▪ article How old is the game of billiards? Detailed answer ▪ article Basic resuscitation in children. Health care ▪ article Electrician's tool. Encyclopedia of radio electronics and electrical engineering ▪ article Paper tree. Focus Secret

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

See other articles Section

See other articles Section