|

|

HISTORY OF TECHNOLOGY, TECHNOLOGY, OBJECTS AROUND US

Mechanical watches. History of invention and production

Directory / The history of technology, technology, objects around us The creation of mechanical watches was of great importance for the history of technology. The point is not so much that people have at their disposal a convenient device for measuring time. The impact of this invention was incomparably wider. The clock was the first automatic machine created for practical purposes and widely used. For three whole centuries they remained the most complex technical device and, like a magnet, they attracted the creative thought of mechanics. There was no other such field of technology where so much ingenious ingenuity, knowledge and wit would be applied as in the creation and improvement of the clock mechanism. Therefore, it will not be a big exaggeration to say that the XIV-XVII centuries in the history of technology passed under the sign of the clock. For technology itself and its creators, it was a time of maturity. Compared to earlier primitive devices, watches have become, as it were, a big qualitative step forward. Their creation required complex calculations and painstaking work, special tools and new materials, they provided an excellent opportunity to combine science and practice.

Many design ideas, which later became widespread in other branches of technology, were first tested in watches, and for many mechanisms created in subsequent times, watches served as a model. They were, as it were, an experimental model of all mechanical art in general. It is difficult to name any other device that provided such a rich field for the work of human thought. Various devices for measuring time were created in ancient times. The immediate forerunners of the mechanical clock, which prepared their invention, were the water clock. Complex water clocks already used a dial with an arrow moving along it, a load as a driving force, wheel gears, a fighting mechanism and puppets that played various scenes. So, for example, a real technical masterpiece of its time was a water clock presented to Charlemagne by Caliph Harun al-Rashid. Richly decorated, they had an hour dial and announced every hour with a sonic boom of a metal ball that popped up on a decorative grille. At noon, the gates opened at this clock and the knights rode out of them. In medieval chronicles there are many references to other witty designs of water clocks. However, a real revolution in technology and chronometry occurred, as already mentioned, only after the advent of wheeled mechanical watches.

The first mention of a tower wheel clock in Europe falls on the border of the 1th and 2th centuries. Could such a watch have appeared earlier? To answer this question, let's look at the main components of a watch mechanism. There are six such main units: 3) engine; 4) transmission mechanism of gears; 5) a regulator that creates a uniform movement; 6) distributor, or descent; XNUMX) a pointer mechanism; and XNUMX) a mechanism for shifting and winding hours.

The first watch mechanisms were driven by the energy of a descending load. The drive mechanism consisted of a smooth wooden shaft and a hemp rope wound around it with a stone and later a metal weight at the end. Due to the gravity of the weight, the rope began to unwind and rotated the shaft. A large or main gear was mounted on the shaft, which was in engagement with the gears of the transmission mechanism. Thus, the rotation from the shaft was transmitted to the clock mechanism. Already before we mentioned that the period of rotation of the wheels in a gear train depends on the ratio of the diameters of the wheels included in it (or, what is the same, the ratio of the number of teeth). By selecting wheels with different numbers of teeth, it is easy to achieve, for example, that one of them makes a revolution in exactly 12 hours. If you put an arrow on the shaft of this wheel, then it will complete a full revolution in the same time. It is clear that it is also possible to pick up wheels that make a complete revolution in a minute or an hour; with them you can connect the second and minute hands. But such watches appeared much later - only in the XNUMXth century, and before that a single hour hand was used. The purpose of the transmission mechanism in such watches was to transmit and convert accordingly the movement from the main gear to the hour wheel. However, in order for a watch to be able to measure time, the hand must make its revolutions with the same frequency. Meanwhile, the load, as it is well known to all, moves under the action of forces of attraction with acceleration. If the weight fell freely, then the shaft would rotate rapidly, respectively, the arrow would make each next revolution in a shorter time than the previous one. Faced with this problem, medieval mechanics (although they had no idea about acceleration) realized that the movement of the clock could not depend only on the movement of the load. The mechanism had to be supplemented with another device. This device had to have its own, independent "sense of time" and, in accordance with this, control the movement of the entire mechanism. Thus, the idea of the regulator was born. If a modern person is asked what the simplest device is most appropriate to use as a regulator, he will most likely name a pendulum. Indeed, the pendulum satisfies the set conditions best of all. This can be verified by a simple experiment. If a ball tied to a sufficiently long thread is deflected through a small angle and released, it will begin to oscillate. Armed with a stopwatch, you can calculate how many oscillations the pendulum will make, for example, in every fifteen seconds. Continuing observations for one and a half to two minutes, it is easy to see that all measurements coincide. Due to friction against the air, the range of oscillations of the ball will gradually decrease, but (and this is very important!) The duration of the oscillation will remain unchanged. In other words, the pendulum has a wonderful "sense of time". However, for a very long time these remarkable properties of the pendulum were unknown to mechanics, and pendulum clocks appeared only in the second half of the XNUMXth century. In the first mechanical watches, a yoke (bilyanets) served as a regulator. Since ancient times, the rocker has been used in such a widespread device as scales. If equal weights are placed on each arm of such rocker balances, and then the scales are taken out of equilibrium, the rocker will make fairly equal oscillations like a pendulum. Although this oscillatory system is inferior in many respects to the pendulum, it may well be used in clocks. But any regulator, if you do not constantly maintain its fluctuations, sooner or later will stop. In order for the clock to work, it is necessary that part of the motive energy from the main wheel is constantly supplied to the pendulum or bilyants. This task in the clock is performed by a device called a distributor, or escapement.

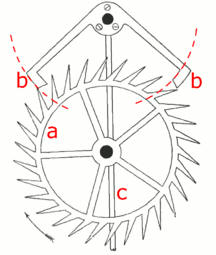

The escapement has always been and remains the most difficult part of a mechanical watch. Through it, a connection is made between the regulator and the transmission mechanism. On the one hand, the descent transmits the impulses from the engine to the regulator, necessary to maintain the oscillations of the latter, and on the other hand, it subordinates the movement of the transmission mechanism (and, consequently, the action of the engine) to the laws of the movement of the regulator. The correct running of the clock depends mainly on the descent. It was over its design that the inventors puzzled the most. The very first descent was a spindle with raids, which is why it is called the spindle. The principles of its operation will be described in detail below. In the first hours there was no special winding mechanism. As a result, preparing the watch for work required a lot of effort. Not only did we have to lift a very heavy weight to a considerable height several times a day, we also had to overcome the enormous resistance of all the gear wheels of the transmission mechanism. (It is clear that the main wheel, if it sits rigidly on the motor shaft, will rotate with the shaft when the weight is lifted, and the rest of the wheels will rotate with it.) Therefore, already in the second half of the XNUMXth century, the main wheel began to be fixed in such a way that when reverse rotation of the shaft (counterclockwise), it remained motionless. Of the six main components of the clock mechanism described by us, most of them were already used individually in antiquity. Only two inventions were new: the idea of hanging a weight as a watch engine, and the idea of using a spindle as an escapement. It is curious that medieval legend attributes both of these technical findings to one person - the learned monk Herbert of Avrilak, who later became pope under the name of Sylvester II. It is known that Herbert was very interested in clocks all his life and in 996 he assembled the first tower clock in history for the city of Magdeburg. Since these watches have not been preserved, the question remains open to this day - what principle of action they had. Most modern researchers are sure that they were mermen. This is also supported by the fact that the next tower clock, which with more or less reason can be considered mechanical, did not appear in Europe until three hundred years later. However, on the other hand, if Herbert really was such a good mechanic as they write about him, if he really invented the spindle escapement, and if he really thought a lot about the scheme of mechanical watches, it is completely incomprehensible what could prevent him from assembling such watches, since he had everything you need for this. But be that as it may, the era of mechanical watches began in Europe only at the end of the 1288th century. In 1292, a clock tower was installed in Westminster Abbey in England. In 1300 a clock was added to the church at Canterbury. In 1314, there is a message that the tower clock was built in Florence (the mention of this clock was preserved in Dante's Divine Comedy). In XNUMX, the clock was already in French Cannes. None of these early mechanisms have survived to this day, the names of their creators are also unknown. However, we can quite accurately imagine their structure. The simplest clock mechanism (if you do not take into account the mechanism of the battle) may include only three gears. Obviously, all the watches mentioned above were an example of a simple three-wheeled movement with a single-hand dial. From the main wheel, seated on the motor shaft, the movement was transmitted to a small gear, which was on the same axis as the crown (or running) wheel, which was equipped with teeth shaped like saw teeth and located perpendicular to the wheel axis. This wheel was an integral part of the escapement, or spindle escapement, which had the task of regulating the speed of the gear. The crown wheel, receiving energy from the gear, expended it on the rotation of the spindle, with which it was in constant communication. The spindle was equipped with two pallets placed on it against the lower and upper teeth of the crown wheel. Pallets with respect to each other were located at an angle of 90 degrees and alternately engaged the teeth of the crown wheel, causing the spindle with pallets to rotate in one direction or the other. When, for example, the protruding tooth of the wheel collided with the lower pallet and hit it, this led to the rotation of the spindle on its axis and, consequently, to the fact that the upper pallet after a while entered the gap between the teeth located at the top of the wheel. The pressure exerted by the top tooth reversed the rotation of the spindle. The tooth of the travel wheel was released with each such turn of the spindle. But the wheel immediately came into contact with another pallet, and so the whole process was repeated again. With each turn of the spindle, the wheel had time to turn only one tooth. The speed of rotation of the spindle was determined by the regulator, which was, as already mentioned, a rocker with loads moving along it. If the weights were moved closer to the axis, the spindle began to turn faster, and the clock speeded up. If the loads were moved closer to the edge, the clock slowed down. This was the concept of early mechanical watches. But very soon their device became noticeably more complicated. First of all, the number of wheels of the transmission mechanism has increased. This was due to the fact that with a significant difference in the number of teeth between the driving and driven wheels, very large gear ratios were obtained, the mechanism experienced a heavy load and quickly wore out. The load in such watches fell very quickly and had to be raised five or six times a day. In addition, to create large gear ratios, wheels of too large diameter were required, which increased the dimensions of the watch. Therefore, they began to introduce intermediate additional wheels, the task of which was to smoothly increase the gear ratios. Let's look, for example, at the design of de Vic's clock, installed in 1370 in the royal palace in Paris. A rope with a weight B at the end was wound around a wooden shaft A, about 30 cm in diameter. A weight of about 500 pounds (200 kg) was dropped from a height of 10 m in 24 hours. Large weights were required due to significant friction in the wheel engagement and the presence of a heavy-weight Bilyantse regulator. All watch parts were made by blacksmiths on an anvil. On the shaft A was the main wheel E, which transmitted rotation to the rest of the wheels of the mechanism. To facilitate winding, it was not rigidly connected to the shaft, but by means of a pawl F and a ratchet wheel G. Thus, rotating clockwise, the shaft set the wheel E in motion, and turning counterclockwise left it free. To wind the watch, a gear wheel C was used, coupled with gear D. It facilitated the rotation of the handle. The large wheel set in motion the gear sitting on the axle where the second wheel - H was located, and this last one set in motion the gear located on the axle where the third or running wheel I sat. here in the same way as described above.

The tower clock was a rather capricious mechanism that required constant monitoring. The load had to be lifted several times during the day. The course of the watch depended on the force of friction, so they needed constant lubrication. The error of their daily course by modern standards was very large. But, despite this, for a long time they remained the most accurate and common instrument for measuring time. With every decade, the watch mechanism became more complicated. Many other devices that performed a variety of functions began to be associated with watches. In the end, the clock tower developed into a complex device with many hands, automatic moving figures, a varied chiming system, and magnificent decorations. They were masterpieces of technology and art at the same time. For example, the famous master Junello Turriano needed 1800 wheels to create a tower clock that reproduced the daily movement of Saturn, the hours of the day, the annual movement of the Sun, the movement of the Moon, as well as all the planets in accordance with the Ptolemaic system of the universe. In other hours, puppets played real theatrical performances.

So, in the Prague Clock Tower (built in 1402), before the fight, two windows above the dial were opened and 12 apostles came out of them. The terrible figure of Death, standing on the right side of the dial, turned the scythe, and then the hourglass, with each strike of the clock, reminding of the end of life. The man standing next to him nodded his head, as if emphasizing the fatal inevitability. On the other side of the dial were two more figures. One depicted a man with a wallet in his hands; every hour he rang the coins lying there, showing that time is money. Another figure depicted a traveler rhythmically striking the ground with his staff. She showed how, over time, a person moves along the path of life, or the vanity of life. After the chiming of the clock, a rooster appeared and crowed three times. Christ was the last to appear in the window and blessed all the spectators standing below. The creation of such automata required special software devices. They were set in motion by a large disk controlled by a clockwork. All moving parts of the figures had their own levers. During the rotation of the circle, they rose and then fell when the levers fell into special cutouts and teeth of the rotating disk. In addition, the tower clock had a separate mechanism for the fight (many clocks differently beat a quarter of an hour, an hour, noon and midnight), driven by its own weight, and four dials (on each side of the tower). In the second half of the XNUMXth century, the very first references to the manufacture of watches with a spring engine, which paved the way for the creation of miniature watches, date back. The source of driving energy in a spring watch was a wound and tending to turn around spring, which was an elastic, carefully hardened steel tape, rolled around a shaft inside the drum. The outer end of the spring was attached to a hook in the wall of the drum, while the inner end was connected to the drum shaft. In an effort to turn around, the spring rotated the drum and the gear wheel associated with it, which in turn transmitted this movement to the gear system up to and including the regulator. When designing such watches, the craftsmen had to solve several complex technical problems. The main one concerned the operation of the engine itself. Indeed, for the correct running of the clock, the spring must act on the wheel mechanism with the same force for a long time. To do this, you need to make it unfold slowly and evenly. The impetus for the creation of spring watches was the invention of constipation, which did not allow the spring to straighten out immediately. It was a small latch that fit into the teeth of the wheels and allowed the spring to unwind only so that its entire body turned at the same time, and with it the wheels of the clock mechanism.

Since the spring has an unequal force of elasticity at different stages of its deployment, the first watchmakers had to resort to various ingenious tricks to make its course more uniform. Later, when they learned how to make high-quality steel for watch springs, they were no longer needed. (Now in inexpensive watches, the spring is simply made long enough, designed for about 30-36 hours of operation, but it is recommended to wind the watch once a day at the same time. only used in the middle part when the force of its elasticity is more uniform.)

The most significant improvements in the clock mechanism were made in the second half of the XNUMXth century by the famous Dutch physicist Huygens, who created new regulators for both spring and weight clocks. The yoke, which had been used for several centuries before, had many shortcomings. It is even difficult to call him a regulator in the proper sense of the word. After all, the regulator must be capable of independent oscillations with its own frequency. The rocker was, generally speaking, only a flywheel. Many extraneous factors influenced his work, which was reflected in the accuracy of the watch. The mechanism became much more perfect when a pendulum was used as a regulator.

For the first time, the idea to use a pendulum in the simplest instruments for measuring time came to the great Italian scientist Galileo Galilei. There is a legend that in 1583 the nineteen-year-old Galileo, while in the Pisa Cathedral, drew attention to the swinging of the chandelier. He noticed, counting the beats of the pulse, that the time of one oscillation of the chandelier remained constant, although the swing was getting smaller and smaller. Later, starting a serious study of pendulums, Galileo found that with a small swing (amplitude) of swing (only a few degrees), the period of oscillation of the pendulum depends only on its length and has a constant duration. Such oscillations became known as isochronous. It is very important that in isochronous oscillations the period of oscillation of the pendulum does not depend on its mass. Thanks to this property, the pendulum turned out to be a very convenient device for measuring short periods of time. On its basis, Galileo developed several simple counters that he used in his experiments. But due to the gradual damping of the oscillations, the pendulum could not serve to measure long periods of time. The creation of the pendulum clock consisted in connecting the pendulum to a device for maintaining its oscillations and counting them. At the end of his life, Galileo began to design such watches, but things did not go further than developments. The first pendulum clocks were created after the death of the great scientist by his son. However, the device of these watches was kept in strict confidence, so they did not have any influence on the development of technology. Independently of Galileo, Huygens assembled a mechanical pendulum clock in 1657. When replacing the rocker with a pendulum, the first designers faced a difficult problem: as already mentioned, the pendulum creates isochronous oscillations only at a small amplitude, while the spindle escapement required a large span. In the first hours of Huygens, the swing of the pendulum reached 40-50 degrees, which adversely affected the accuracy of the movement. To compensate for this shortcoming, Huygens had to show miracles of ingenuity. In the end, he created a special pendulum, which, during the swing, changed its length and oscillated along a cycloid curve. Huygens's clock was incomparably more accurate than a rocker clock. Their daily error did not exceed 10 seconds (in watches with a yoke regulator, the error ranged from 15 to 60 minutes). Around 1676, the English watchmaker Clement invented the anchor escapement, which was very well suited to the pendulum clock, which had a small oscillation amplitude. In this design of the descent, an anchor with pallets was mounted on the axis of the pendulum. Swinging along with the pendulum, the pallets were alternately introduced into the running wheel, subordinating its rotation to the period of the pendulum's oscillation. With each oscillation, the wheel had time to turn one tooth. Thanks to this trigger mechanism, the pendulum received periodic shocks that did not allow it to stop. The push occurred whenever the running wheel, freed from one of the anchor teeth, hit the other tooth with a certain force. This push was transmitted from the anchor to the pendulum.

The Huygens pendulum regulator revolutionized watchmaking technology. Later, Huygens worked hard to improve pocket spring watches. The main problem facing watchmakers at that time was to create their own regulator for pocket watches. If even in a stationary tower clock the rocker was considered insufficiently suitable, then what could be said about a pocket watch that was constantly in motion, swaying, shaking and changing its position? All these fluctuations had an effect on the course of the clock. In the XNUMXth century, watchmakers began to replace the two-arm bilyany in the form of a rocker arm with a round flywheel. This improved the performance of the clock, but it remained unsatisfactory. An important improvement in the regulator occurred in 1674, when Huygens attached a spiral spring - a hair - to the flywheel. Now, when the wheel deviated from the neutral position, the hair acted on it and tried to return it to its place. However, the massive wheel slipped through the point of balance and spun in the other direction until the hair pulled it back again. Thus was created the first balance regulator or balancer with properties similar to those of a pendulum. Removed from the state of equilibrium, the wheel of the balance wheel began to make oscillatory movements around its axis. The balancer had a constant period of oscillation, but unlike the pendulum, it could work in any position, which is very important for pocket and wrist watches. Huygens' improvement made the same revolution among spring clocks as the introduction of a pendulum into stationary wall clocks.

The new regulator required a new escapement design. In the decades that followed, various watchmakers developed several ingenious escapements. The simplest cylindrical escapement for spring watches was invented in 1695 by Thomas Tompion.

The Tompion's starter wheel was equipped with 15 specially shaped "legged" teeth. The cylinder itself was a hollow tube, the upper and lower ends of which were tightly packed with two tampons. On the lower tampon, a balancer with a hair was planted. When the balancer oscillated to the right and to the left, the cylinder also rotated in the corresponding direction. There was a 150-degree cutout on the cylinder, passing at the level of the teeth of the escapement wheel. When the wheel moved, its teeth alternately entered the cylinder cutout one after the other. Thanks to this, the isochronous movement of the cylinder was transmitted to the escape wheel and through it to the entire mechanism, and the balancer received impulses that supported its oscillations. Author: Ryzhov K.V.

Artificial leather for touch emulation

15.04.2024 Petgugu Global cat litter

15.04.2024 The attractiveness of caring men

14.04.2024

▪ LeTV X1 door lock with 3D face ID ▪ Learning ability can be seen in the eyes ▪ MAX17558 Dual Channel 60V DC-DC Buck Controller ▪ See, Smell, Touch - Tomorrow's TV

▪ section of the site Cultivated and wild plants. Article selection ▪ article Jester pea. Popular expression ▪ article Which bird speaks better? Detailed answer ▪ article Economist of a trade enterprise. Job description ▪ article Hybrid linear power amplifier. Encyclopedia of radio electronics and electrical engineering

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

See other articles Section

See other articles Section