|

|

HISTORY OF TECHNOLOGY, TECHNOLOGY, OBJECTS AROUND US

Diesel. History of invention and production

Directory / The history of technology, technology, objects around us Diesel engine (diesel) - a reciprocating internal combustion engine operating on the principle of self-ignition of atomized fuel from the action of air heated during compression. The range of fuel for diesel engines is very wide, it includes all fractions of oil refining from kerosene to fuel oil and a number of products of natural origin - rapeseed oil, cooking fat, palm oil and many others. A diesel engine can run on crude oil with some success.

As you know, one of the main indicators by which the operation of any engine, including a thermal one, is evaluated is its efficiency. The more energy released during the combustion of fuel is converted into useful work, the less it is lost during various transformations, the better. In all existing heat engines, these losses are very high, so that more than two-thirds of the energy released in them is wasted. What is the reason here? Is this due to poor design, or can a heat engine in principle not be highly efficient by its very nature? For the first time, the French engineer Carnot, who published in 1824 the classic work Reflections on the Driving Force of Fire, thought about this issue. Carnot set himself the task of finding out how the processes should proceed in an ideal heat engine so that its efficiency is as high as possible. Through calculations, he eventually deduced the concept of a circular process in the operation of all heat engines (it is called the "Carnot cycle"), in which between two temperatures T1 and T2 of the working fluid of the engine (the working fluid is the gas that moves the piston; it can be steam in a steam engine or an explosive mixture in a gas engine), you can get the maximum useful work, and therefore the highest efficiency.

The work of this hypothetical high-efficiency engine, as Carnot proved, should consist of four cycles. In the first cycle, heat Q1 is supplied to the working fluid from the upper level T1 at a constant temperature of this level (that is, in this cycle, the working fluid must expand while maintaining a constant temperature, which is achieved by heating the body). During the second cycle, the working fluid expands, but without heat supply, until its temperature drops to the lower level T2. In the third cycle, the working fluid is compressed at a constant temperature T2 (for this it was necessary to constantly remove heat Q2). At the fourth stage, the working fluid was compressed without heat removal until its temperature rose again to T1. If all these conditions were met, according to Carnot's calculations, the efficiency of the engine was determined by the formula 100•(1 - T2/T1) and reached about 70-80%. Throughout the 100th century, Carnot's calculations excited the creative thought of inventors who tried to find an answer to the question: how to bring the work of real heat engines closer to work on the "Carnot cycle" and get the highest possible efficiency. But all attempts to build such an engine were unsuccessful. For example, the efficiency of a steam engine at a power of 13 hp. did not exceed 10%, and in low-power engines it was less than 22%. The efficiency of gasoline and gas engines turned out to be somewhat higher, but also did not exceed 24-XNUMX%. Such was the state of affairs when, in the early 90s, the young German engineer Rudolf Diesel took up the creation of the "ideal engine". While still a student, he set himself the goal of developing such an engine, the performance of which would be close to the "Carnot cycle", and this engine should have surpassed a conventional gasoline engine both in power and in efficiency. After several years of hard work, the engine design was developed. The essence of Diesel's idea was as follows. At the first stage, the piston compresses the air in the cylinder to a high pressure, due to which the temperature in the cylinder rises to the ignition temperature of the fuel (this corresponded to the fourth Carnot cycle - compression without heat removal). Thus, a pressure of about 90 atm and a temperature of about 900 degrees were achieved in the cylinder. Fuel was supplied to the cylinder at the end of the compression cycle and, due to the high air temperature, ignited from one contact with it without any external ignition. The injection of fuel was carried out evenly, so that part of the reverse movement of the piston and the expansion of gases occurred at a constant temperature (in accordance with the first "Carnot cycle"). Further, the piston moved already under the influence of high pressure without burning fuel (the second "Carnot cycle"). The third cycle corresponded to the exhaust and suction of a fresh portion of atmospheric air. Then all cycles were repeated. Thanks to such a device, Diesel thought to increase the efficiency of his motor to an unheard of value - 73%. At first, he expected to use ammonia vapor as a fuel, but then he chose coal powder. In 1892, Diesel received a patent for the described principle of operation of the engine, and in 1893 he published the brochure "Theory and Design of a Rational Heat Engine" with a description of the motor and his mathematical calculations.

The brochure attracted a lot of attention. However, most engineers considered Diesel's idea unrealizable. The largest specialist in gas engines of that time, Koehler, warned that it was impossible to obtain such a high efficiency, since the Diesel engine has very high power losses for compressing air to the ignition temperature, and when working on the "Carnot cycle" all useful work will be spent only on maintaining its own movement. Nevertheless, Diesel began to aggressively offer his model to various German firms. At first, he was met with rejection everywhere. Without despair, he continued the correspondence, argued, argued, and finally succeeded: the Krupp firm in Essen agreed to finance the costs, and the management of the Augsburg plant to produce a test sample. Already in July 1893, the first single-cylinder diesel engine was manufactured. In accordance with the original design, the compression in its cylinder was to reach 90 atm, and the temperature before the start of fuel intake was 900 degrees. Since the temperature should not have greatly exceeded this limit, no cooling system was provided for the motor. The compressor was also not planned - coal powder was supposed to be blown in by a pump. But even at the assembly stage, Diesel, having checked his calculations, was convinced that Koehler was right - the engine power consumption for compressing air up to 90 atmospheres turned out to be excessively high and "ate" the entire gain in efficiency due to work on the "Carnot cycle". I had to redo my plan on the go. In order to reduce the loss of power for compression, Diesel decided to reduce the pressure in the cylinder by more than half - up to 35-40 atm. In this regard, the temperature of the compressed air instead of 900 degrees should have been only 600. This was very small - the temperature difference in the Carnot formula turned out to be too small to obtain high efficiency. In order to improve the situation and increase the power of the engine, Diesel had to abandon the second important point of his design - the expansion of the working fluid at a constant temperature. He calculated that the temperature during the combustion of fuel should increase to 1500 degrees. And this, in turn, required, firstly, the most intensive cooling of the engine, and secondly, more high-calorie fuel. Coal dust could not give such a high temperature, so Diesel was forced to turn to liquid fuel. But at the first attempt to inject gasoline into the cylinder, an explosion occurred that almost claimed the lives of the inventor and his assistants. Thus ended the first test. It had two results. Diesel had to deviate quite a bit from the original scheme of his "ideal engine" step by step. But, on the other hand, some fundamental points of his calculations were confirmed - a strong compression of the working mixture led to an increase in efficiency and, in addition (the explosion proved this), it turned out that the fuel can indeed be ignited by compression without resorting to an expensive ignition system. Therefore, the firms that financed the project were generally satisfied with the success achieved, and Diesel was able to continue his experiments.

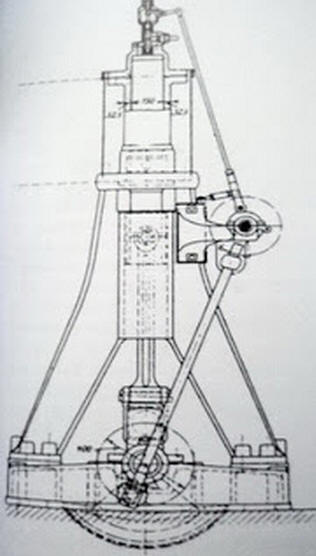

In June 1894, a second engine was built, for which Diesel invented a nozzle that controlled the injection of kerosene. In this model, the pressure in the cylinder was brought up to 35-40 atm, and the temperature at the end of compression - up to 500-600 degrees. The motor was not only able to start, but also to make it idle at a frequency of up to 80 rpm. It was a great success - Diesel's idea proved to be viable. In 1895, a third engine was built, which could already work with a small load. For the injection of kerosene, a compressor was provided here for the first time. In addition, an intensive cooling system had to be developed to prevent the cylinder from jamming. Only after that, in 1896, the launch of a new prototype brought success. When tested with a load, the efficiency of the motor turned out to be 36%, and the consumption of kerosene was about 200 g per horsepower per hour. Although these figures were very far from the parameters of the "ideal motor", they were still impressive: the efficiency of the new engine turned out to be 10-12% higher than that of gasoline engines of that time, and in terms of its efficiency it exceeded them almost twice. Although Diesel failed to fulfill his dream, nevertheless, what he did was of great importance - thanks to his perseverance, a fundamentally new design of the internal combustion engine was developed, which has been and remains the best over the past hundred years. The new motor worked as follows. During the first stroke of the piston, due to the manpower of the flywheel stored for the previous operation of the machine, air was sucked into the cylinder. During the second stroke, also due to the manpower of the flywheel, the air trapped in the cylinder was compressed to 35 atm. At the same time, the heat released during compression brought it to the ignition temperature of the fuel. At the beginning of the third stroke, kerosene was introduced using a pump. This injection lasted only a small part of the stroke. During the rest of the stroke, the gas mass expanded, and the working force was imparted to the piston, which was transmitted through the connecting rod to the engine crankshaft. In the fourth stroke, the products of combustion erupted through the exhaust pipe into the atmosphere. The engine was equipped with a compressor, which in a special reservoir condensed air at a pressure slightly higher than the highest pressure in the cylinder. From this reservoir, air was directed through a tube of very small diameter into a small nozzle chamber, that is, an apparatus for spraying the supplied fuel, into which kerosene was simultaneously supplied. This chamber communicated with the interior of the cylinder through a small hole closed by a needle: when this needle was raised, the kerosene was forced into the cylinder due to the excess pressure in the chamber. The combustion in the cylinder was regulated, depending on the force that the engine had to develop, either by changing the duration of the fuel intake, or by changing the pressure in the compressor. The same compressed air was also used for the initial start of the engine from a cold state. On top of the engine was a camshaft with five cams, one controlled the valve that let in air, the other - the valve that let in kerosene, the third - the valve that released combustion products. The last two cams controlled the valves by which compressed air was admitted into the cylinder during the initial start of the engine.

The very first official tests of the new engine made a real sensation among the engineers. Since that time, the victorious march of "diesels" around the world began. Many firms that had not previously responded to Diesel's proposal were in a hurry to buy from him the right to build the engines he invented, and this right now cost them dearly (for example, Emmanuel Nobel, wanting to establish diesel production in Russia, paid Diesel about 500 thousand dollars). Already in 1898, Diesel, quite unexpectedly for himself, became a millionaire. However, the first engines put into mass production turned out to be unsatisfactory, capricious and often failed. The release of such a complex and high-tech machine was beyond the power of many factories with outdated equipment. Like Watt in his time, Diesel had to spend a lot of effort to perfect the production process for manufacturing diesel engines - to develop new machines, find suitable alloys, and train specialists. For several years he wandered around Europe and America, visiting the factories where his motors were manufactured. By the beginning of the 1900th century, the main difficulties had been overcome, and diesel engines began to gradually conquer more and more new areas of application in industry and transport. In XNUMX, at the World Exhibition in Paris, Diesel engines received the Grand Prix. The prestige of new engines was especially raised by the news that the Nobel plant in Russia had launched the production of very good engines that ran on crude oil. Author: Ryzhov K.V.

▪ Dynamite

Artificial leather for touch emulation

15.04.2024 Petgugu Global cat litter

15.04.2024 The attractiveness of caring men

14.04.2024

▪ The computer was taught to distinguish male text from female ▪ The updated line of Wireless Plus from Seagate ▪ Efficient hemp supercapacitors ▪ Repetitive routes will reduce the fuel consumption of hybrid cars

▪ section of the site Funny puzzles. Article selection ▪ article In all of you, darling, you are good attire! Popular expression ▪ article Which pet lives in Afghanistan in only one copy? Detailed answer ▪ article Common bird cherry. Legends, cultivation, methods of application ▪ article Chinese ink. Simple recipes and tips ▪ article Sevens and kings change places. Focus Secret

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

See other articles Section

See other articles Section