|

|

HISTORY OF TECHNOLOGY, TECHNOLOGY, OBJECTS AROUND US

Matches. History of invention and production

Directory / The history of technology, technology, objects around us A match is a stick (stalk, straw) made of combustible material, equipped with an incendiary head at the end, which serves to produce an open fire.

Matches have been one of the most important elements of human life for many decades, and even today they play an important role in our everyday life. Usually, striking a match on a box, we do not even think about what chemical reactions are taking place at that second and how much ingenuity and effort people have put in to have such a convenient means of making fire. Ordinary matches are undoubtedly among the most amazing inventions of the human mind. To be convinced of this, it suffices to recall how much effort it took to make a fire in the old days. True, our ancestors abandoned the tedious method of extracting fire by friction even in antiquity. In the Middle Ages, a more convenient device appeared for this purpose - a steel, but even with it, kindling a fire required a certain skill and effort. When steel hit flint, a spark was struck, which fell on tinder soaked in saltpeter. The tinder began to smolder. Having attached a piece of paper, shavings or any other kindling to it, they fanned the fire. Fanning the spark was the most unpleasant moment in this lesson. But was it possible to do without it? Someone came up with the idea of dipping a dry splinter into molten sulfur. As a result, a sulfur head formed on one tip of the torch. When the head was pressed against the smoldering tinder, it flared up. The whole splinter lit up from it. This is how the first matches appeared. I must say that throughout their previous history, people tried to get fire with the help of mechanical influences - friction or impact. With this approach, the sulfur match could only play an auxiliary role, since it was impossible to directly make fire with its help, because it did not catch fire either from impact or friction. But at the end of the XNUMXth century, the famous chemist Berthollet proved that a flame can be the result of a chemical reaction. In particular, if sulfuric acid is dropped on potassium hypochlorous acid (Bertholite salt), a flame will arise. This discovery made it possible to approach the problem of making fire from a completely different angle. In different countries, many years of research began to create matches with an end smeared with one or another chemical substance that can ignite under certain conditions. In 1812, Chapsel invented the first self-igniting matches, still very imperfect, but with their help it was possible to get a flame much faster than with the help of a steel. Chapsel's matches were wooden sticks with a head made of a mixture of sulfur, bartolet salt and cinnabar (the latter served to color the incendiary mass in a beautiful red color). In sunny weather, such a match was lit with a biconvex lens, and in other cases, in contact with a drop of concentrated sulfuric acid. These matches were very expensive and, moreover, dangerous, since sulfuric acid splashed when the head ignited and could cause burns. It is clear that they are not widely used. More practical were to be matches with heads that light up with light friction. However, sulfur was not suitable for this purpose. They were looking for another flammable substance and then drew attention to white phosphorus, discovered in 1669 by the German alchemist Brand. Phosphorus is much more combustible than sulfur, but not everything worked out right away with it. At first, matches were lit with difficulty, as the phosphorus burned out too quickly and did not have time to ignite the torch. Then they began to apply it over the head of an old sulfur match, assuming that sulfur would catch fire faster from phosphorus than wood. But these matches also lit up badly. Things went smoothly only after they began to mix with phosphorus substances that, when heated, release the oxygen necessary for ignition. Now it is difficult to say who was the first to come up with a successful recipe for incendiary mass for phosphorus matches. Apparently, it was the Austrian Irini. In 1833, he suggested to the entrepreneur Roemer the following method for making matches: “You need to take some hot glue, gum arabic is best, throw a piece of phosphorus into it and shake the bottle with glue vigorously. In hot glue, with strong shaking, phosphorus will break into small particles. They stick together so closely with glue that a thick whitish liquid is formed.Further, finely ground lead peroxide powder must be added to this mixture.All this is stirred until a uniform brown mass is obtained. covered with sulfur. Sulfur should be covered with a layer of phosphorus mass on top. To do this, sulphurs are dipped in the prepared mixture. Now it remains to dry them. In this way, matches are obtained. They ignite very easily. They just need to be struck against the wall. " This description enabled Roemer to open a match factory. However, he understood that it was inconvenient to carry matches in his pocket and strike them against the wall and came up with the idea of packing them in boxes, on one side of which they glued a rough piece of paper (they simply prepared it - they dipped it in glue and poured sand or crushed glass on it). When striking on such a piece of paper (or on any rough surface), the match ignited. Having set up a trial production of matches to begin with, Remer then expanded production forty times - so great was the demand for his goods, and earned a lot of money from the production of matches. Other manufacturers followed his example, and soon phosphorus matches became a popular and cheap commodity in all countries.

Gradually, several different compositions of the incendiary mass were developed. Already from the description of Irini it is clear that the head of the phosphorus match included several components, each of which performed its own functions. First of all, there was phosphorus, which played the role of an igniter. Substances that release oxygen were mixed with it. In addition to the rather dangerous berthollet salt, manganese peroxide or red lead could be used in this role, and in more expensive matches, lead peroxide, which was generally the most suitable material. Less combustible substances were placed under a layer of phosphorus, transmitting a flame from an igniter to a wooden torch. It could be sulfur, stearin or paraffin. In order for the reaction not to go too fast and the wood to have time to heat up to the combustion temperature, neutral substances were added, for example, pumice or powdered glass. Finally, glue was mixed into the mass in order to connect all the other components together. When the head rubbed against a rough surface at the point of contact, heat arose sufficient to ignite the nearest particles of phosphorus, from which others ignited. At the same time, the mass was so heated that the body containing oxygen decomposed. The released oxygen contributed to the ignition of a flammable substance that was under the head (sulfur, paraffin, etc.). From him, the fire was transferred to the tree. Match production from the very beginning took on a large scale, because the annual consumption of matches amounted to tens and hundreds of billions of pieces. It was impossible to do without comprehensive mechanization. The fabrication of matches was divided into two main operations: 1) making sticks (match straws), 2) preparing an incendiary mass and dipping straws into it. The most commonly used type of wood for matches was aspen, as well as poplar, willow, pine, spruce, the wood of which had strong straight fibers. The dried logs were cut into pieces about 1 m long. Each piece was split crosswise into four parts and the bark was removed from it. The resulting block was strengthened on a carpentry workbench and planed with a special planer, the working part of which consisted of several tubes pointed at the front. When such a planer passed along a tree, long round or rectangular sticks were obtained (depending on the shape of the tubes, any cross section could be given to the straw). Then, with an ordinary plane, they smoothed out the irregularities formed in the form of grooves from the pulled out splinters, removed the second layer, leveled the tree again, and so on. The resulting splinter was cut into pieces having the length of a match. This operation was carried out on a machine that had a very simple device.

The splinters were placed in a trough and moved close to the regulating plate, and then, using a lever and a knife, they cut off the set length. Instead of manual planing, a special machine soon began to be used. The tree here rested against the end of the bed and was processed using a cutting device, in which there were several pointed tubes that cut out splinters when the cutting device moved. In order to be processed on this machine, the log was first cut into boards. This machine, however, had many shortcomings and gave a big waste. Therefore, in the future it was replaced by others, and the process of cutting splinters was divided into several operations. For further processing, the straws had to be laid in even and parallel rows. For this purpose, they also used a special machine. On the platform, which received rapid shaking movements, a partitioned box was installed, and the distance between the partitions corresponded to the length of the match. With the rapid movement of the box, the straws were placed between the partitions in the compartments of the box, and the garbage fell through its lower holes. Then the box was removed and turned over. The straw remained on the board in parallel rows and, in this form, was sent to the macula. Before dipping, the straws were placed in a special frame, which consisted of a base and two iron rods attached to it, on which wooden planks were put on. Grooves ran parallel to each other across the boards. The length of these grooves was made such that the straw placed in them protruded by about a quarter of its length. The filled boards were put on the rods one above the other. From above, they were all covered with a board and clamped with wedges. Thus, a frame was obtained in which about 2500 matches were placed. Subsequently, this operation was mechanized and carried out by a special typesetting machine. Each match had to be dipped twice - first in sulfur or paraffin, and then in an incendiary mass. Making an incendiary mass was a complex matter that required great precautions. Of particular importance was its thorough mixing. To do this, each component was heavily crushed to a powder state. Initially, matches were dipped by hand using a dipping pan. The macal frying pan consisted of two parts: flat and recessed. The first was made somewhat larger than the type-setting frame and actually served for dipping into the molten mass. Its layer here was insignificant and corresponded to the height of the waxed (or sulphurized) part of the match. The second part served as a reservoir for the mass and helped to maintain a constant level.

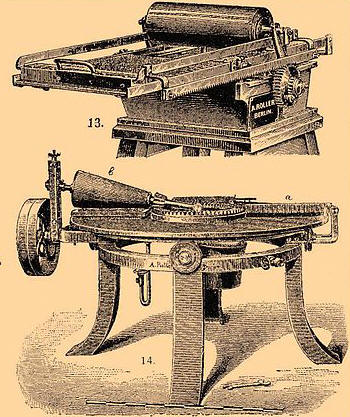

Later, a dipping machine was invented. It consisted of a cast iron tank surrounded by another cast iron tank. The outer tank contained an incendiary mass. Warm water was poured between both reservoirs to warm the mass. The inner tank was closed on all sides and only in the upper board had a transverse slot in which a roller was placed. Rotating, the roller captured with its lower half part of the mass from the tank and applied it to the ends of the matches.

For greater convenience of working on the upper board of the tank, there was a special dipping plate, on which a type-setting frame was installed and which easily moved over the dipping roller with the help of gear racks and gears mounted on the axle of the roller. Another one was placed above the dipping roller, which served to uniformly press the typesetting frames passing under it to the lower roller. From the dipping machine, the typesetting frames were transferred to the drying chamber. After drying, the matches were taken out of the typesetting frames and placed in boxes. For a long time, this work was done manually, but then machines appeared for this operation.

A big disadvantage of phosphorus matches was the toxicity of phosphorus. In match factories, workers quickly (sometimes in a few months) were poisoned by phosphorus vapor and became incapable of work. The harmfulness of this production exceeded even mirror and hat production. In addition, a solution of an incendiary mass in water gave the strongest poison, which was used by suicides (and often murderers). In 1847, Schroeter discovered the non-poisonous amorphous red phosphorus. Since that time, there was a desire to replace dangerous white phosphorus with it. Before others, this problem was solved by the famous German chemist Betcher. He prepared a mixture of sulfur and bartolet salt, mixed them with glue, and applied it to the paraffin-coated splinters. But, alas, these matches turned out to be impossible to light on a rough surface. Then Betcher came up with the idea of smearing a piece of paper with a special composition containing a certain amount of red phosphorus. When the match was rubbed against such a surface, particles of red phosphorus were ignited due to the particles of berthollet salt of the head touching them and ignited the latter. New matches burned with a steady yellow flame. They did not give off any smoke or that unpleasant smell that accompanied phosphorus matches. Betcher's invention at first did not interest the manufacturers. For the first time, "safe matches" began to be produced in 1851 by the Swedes, the Lundstrem brothers. Therefore, phosphorus-free matches were called "Swedish" for a long time. As soon as safety matches became widespread, the production and sale of phosphorus matches was banned in many countries. After a few decades, their production completely stopped. Author: Ryzhov K.V.

▪ Phone ▪ Wipers

Artificial leather for touch emulation

15.04.2024 Petgugu Global cat litter

15.04.2024 The attractiveness of caring men

14.04.2024

▪ Baseus D03 Wireless Over-Ear Headphones ▪ Psychological preparation of parents will help their children ▪ Augmented Reality Contact Lenses

▪ Modeling section of the site. Selection of articles ▪ article Put under the cloth. Popular expression ▪ article How long does it take for a panda to eat? Detailed answer ▪ Article Dental Assistant. Job description ▪ article Homemade spherical lens. physical experiment

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

See other articles Section

See other articles Section