|

|

ENCYCLOPEDIA OF RADIO ELECTRONICS AND ELECTRICAL ENGINEERING Proportional control of the car engine cooling fan. Encyclopedia of radio electronics and electrical engineering

Encyclopedia of radio electronics and electrical engineering / Automobile. Electronic devices The proposed device allows you to switch from the relay principle of controlling the fan of the engine cooling system "the temperature is above the norm - on, below the norm - off" to proportional control, which, according to the author, is more favorable for the engine. Now, as the coolant temperature rises, the fan rotor speed increases linearly. Today, in many automobile engines, the cooling fan is electrically driven, but in most cases it is controlled by a relay principle. Such control has only one advantage - ease of implementation. It is enough to have a temperature sensor with a contact output that controls the fan motor directly or through an intermediate relay. The main disadvantage of this method is a sharp decrease in the temperature of the coolant at the radiator outlet after the fan is turned on. A fan operating at full power lowers the temperature of the coolant at the radiator outlet by 15 ... 25 оWith or more. Entering the engine cooling jacket, the significantly cooled liquid inflicts thermal shock on hot surfaces, which adversely affects the operation of the engine. For its comfortable operation, it is desirable to maintain the temperature of the coolant close to the optimum recommended by the manufacturer, and sudden temperature jumps (thermal shocks) should be excluded in principle. On some vehicles with a mechanically driven cooling fan, this is achieved by connecting the fan to the engine crankshaft through a visco coupling. It changes the torque transmitted to the fan shaft depending on the temperature of the coolant. This stabilizes the temperature. The proposed device is an electronic analogue of a visco-coupling for an electrically driven fan. It automatically adjusts the speed of its rotation depending on the temperature of the coolant. The device operates from the car's on-board network at a voltage of 10...18 V and can control a fan with a maximum current consumption of up to 20 A or up to 30 A, provided that the heat sink area of the power elements is increased. The device's own current consumption does not exceed a few milliamps. The values of the fan switch-on temperature with the minimum rotational speed and the temperature at which the fan rotational speed reaches its maximum are set with a resolution of 0,1 оC when programming the microcontroller. If the coolant temperature sensor fails, the device goes into emergency mode, allowing the engine to safely drive to the repair shop. The scheme of the device is shown in fig. 1. The digital sensor DS18B20 (BK1) measures the temperature. The use of this sensor eliminates the need for calibration of the manufactured device and improves its repeatability.

Temperature information is read from the sensor by the ATtiny2313A-PU (DD1) microcontroller, which is clocked by 1 MHz pulses from an internal RC generator. In proportion to the temperature, it regulates the supply voltage of the fan motor and, consequently, the speed of its rotor. The motor receives a pulsed voltage, the constant component of which, which determines the rotational speed, depends on the duty cycle (the ratio of the duration of the pulses to the period of their repetition). The program sets the duty cycle with eight-bit binary numbers loaded into the comparison register of the microcontroller timer operating in the PWM mode. The pulses generated by the microcontroller control the operation of the power switch on the field-effect transistor VT1, which closes and opens the power supply circuit of the fan motor from the vehicle's on-board network. In this case, the constant component of the voltage applied to the motor is equal to U = U0 (N/255) where U0 - voltage in the on-board network, V; N is the number loaded into the register of the microcontroller. It can be changed in steps ΔU = U0 / 255. With a voltage in the on-board network of 12 V ΔU≈0,05 V, which allows you to adjust the fan speed almost smoothly. To ensure reliable operation of the key transistor VT1 in transient modes, the microcontroller controls it through the TC4420EPA (DA1) driver. Modern field-effect transistors, having a very low open channel resistance (a few milliohms), are able to switch a significant current even without the use of a heat sink. However, the large input capacitance of the field-effect transistor, which for powerful devices reaches several thousand picofarads, is charged and discharged during its switching. This takes the longer, the greater the output impedance of the control signal source. The bad thing is that in the process of recharging the capacitance, the field-effect transistor is in active mode and the resistance of its channel is quite high. Therefore, during the switching time, a significant amount of power is released in the transistor crystal, which can lead to its overheating and irreversible damage. The only way to combat this phenomenon is to speed up the recharge process. To do this, field-effect transistors are controlled through specialized amplifiers (drivers) that have a low output impedance and provide a large (up to several amperes) pulsed charge-discharge current. This ensures fast recharge of the input capacitance of the FET and therefore minimizes the duration of its operation in active mode and reduces the power dissipated on it. Resistor R4 keeps the driver input logic low during microcontroller startup, as long as all its outputs remain in a high-impedance state. This eliminates unnecessary opening of the transistor VT1 at this time. Diode VD1 eliminates self-induction EMF pulses that occur in the windings of the fan motor at the moments of closing the transistor VT1. During operation, the microcontroller program constantly monitors the presence and operability of the temperature sensor. If there is no connection with it, it goes into emergency mode. In this mode, regardless of the temperature of the coolant, the fan will be turned on at full power for 33 seconds, and then turned off for the same time. Of course, this is far from the best way to cool the engine, but it prevents its complete failure in the absence of cooling. The transition to emergency mode is signaled by the HL1 LED turning on. If the failure of communication with the sensor was temporary, after its restoration, the device switches to normal operation. The microcontroller program for fan control contains the following initial data as constants: - Tmin = 87 - coolant temperature, оC, at which the fan should start working at the minimum speed; As you know, industrial sensors designed to control the operation of cooling fans have two main parameters - the on temperature and the off temperature. They should be chosen as TMax and Tmin. The value of N1 must be set in such a way that the constant component of the voltage on the fan motor is equal to its starting voltage Ump. The problem is that it is not customary to indicate the breakaway voltage in the technical data of fans, so the author could not find the value of this parameter in the literature or in the documentation. It had to be determined experimentally. The technique is simple - by applying voltage to the motor, find its value at which the shaft will start to slowly (turn in one or two seconds), but steadily rotate. For most DC motors with a nominal supply voltage of 12 V, the pick-up voltage is in the range of 3...5 V. When starting the program, the microcontroller, based on the values of TMaxTmin and N1 calculates Dn - the required steepness of the dependence of the value of the loaded code timer comparison register on temperature: Dn = (255- N1)/(TMax - Tmin). Then the main loop of the program begins. First of all, there is a check of communication with the temperature sensor, and in its absence, the transition to emergency operation. The program performs such a check every second. If the next check shows that the sensor is working, normal operation is restored. When the sensor is good, it measures the current coolant temperature T. If it is below Tmin, the program turns off the fan, otherwise it calculates the required value of the control code using the formula N = (T - Tmin) Dn+N1. In proportion to it, the duty factor of the voltage supplying the motor and, consequently, the frequency of rotation of its rotor will be set. As a result, the temperature of the coolant at a constant load on the engine is maintained constant. With a variable load, the temperature fluctuates within small limits within the interval Tmin...TMax. All parts of the device, with the exception of the BK1 sensor and the HL1 LED, are placed on a 58x65 mm printed circuit board, the drawing of which is shown in fig. 2, and the arrangement of elements - in fig. 3.

Microcircuits are soldered directly to the board without panels, the use of which is undesirable in conditions of high vibration. The board has contact pads SCK, RST, VCC, MISO, MOSI, GND not shown in the diagram, to which the wires of the same name from the programmer are soldered during the programming of the microcontroller. In this case, the board and the programmer during programming should be powered by +5 V (VCC) from the same source. The board is designed to accept 1206 size resistors and capacitors for surface mounting. Diode SR2040 (URL: files.rct.ru/pdf/diode/5261755198365.pdf) - in a two-pin TO220AC package. Together with the IRF3808 transistor, it is fixed using thermally conductive paste on a common heat sink with a cooling surface area of about 60 cm2. The principle of fastening a transistor 5 or a diode to a heat sink 1 and the entire assembly to a printed circuit board 2 is shown in Fig. 4. The diode is isolated from the heat sink with a mica gasket, and from the fixing screw 4 and the metal sleeve 3 - with an insulating sleeve (insulating elements are not shown in the figure). Between the cases of the diode and the transistor is the third point of attachment of the heat sink to the board. Here it is also fixed with a screw and a sleeve.

All printed conductors of the board, through which the current of the fan motor flows, must be covered with a layer of solder with a thickness of at least 0,7 ... 1 mm, and the cross section of the supply wires must ensure the passage of this current. It is advisable to place the HL1 LED into the car interior so that the driver has up-to-date information about the current mode of operation of the device. The DS18B20 (VK1) sensor should be placed in the housing from the standard contact coolant temperature sensor, from which all the "stuffing" must first be removed. Such a body can also be machined from brass while maintaining overall and connecting dimensions. The placement of the DS18B20 sensor in the housing is shown in fig. 5. Sensor 4 with connector 1 soldered to its terminals is placed in the housing cavity 3 so that its top, on which a layer of thermally conductive paste 5 is applied, touches the bottom of the cavity.

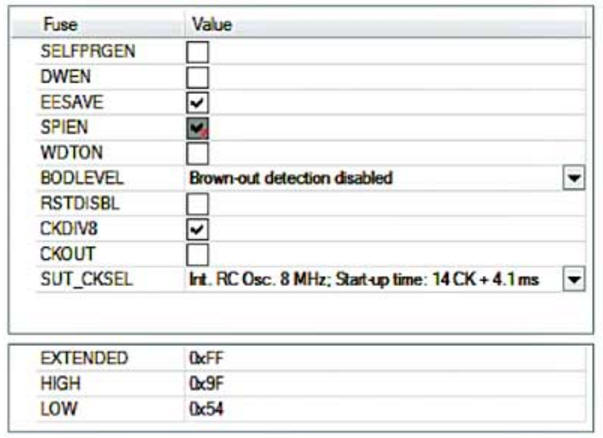

After that, the cavity is filled with a heat-resistant sealant. Connector 1 must have an anti-corrosion coating of contacts, be splash-proof, securely fix the mating part, preventing it from detaching due to vibration. The prepared sensor is installed in place of the regular one. The assembled board is placed in a case of suitable dimensions, which is located in the engine compartment of the car. Ventilation openings are provided in the case. The ATtiny2313A microcontroller can be replaced by another AVR family that has at least one 8-bit and one 16-bit timer and at least 2KB of program memory. Naturally, replacing the microcontroller will require recompiling the program and, possibly, changing the layout of the printed circuit board. Instead of the non-inverting TC4420EPA low-side driver, you can use another similar one, such as the MAX4420EPA. The Schottky barrier diode SR2040 can be replaced with a similar one with a permissible reverse voltage of at least 25 V and a permissible forward current of at least the operating current of the fan. However, Schottky diodes with a reverse voltage of more than 40 V are not recommended, since a larger forward voltage drop across such a diode will lead to an increase in heat dissipation. A replacement for the IRF3808 field effect transistor with an insulated gate and an n-type channel should be selected with an acceptable direct drain current at a temperature of 100 ° C 2,5 ... 3 times the fan operating current and with an open channel resistance at a fan operating current of up to 20 A - not more than 10 mΩ, and 20 ... 30 A - not more than 7 mΩ. The allowable drain-source voltage must be at least 25 V, and the gate-source voltage must be at least 20 V. A device correctly assembled from serviceable parts will require adjustment only if the initial data in the attached version of the program, which was mentioned earlier, do not correspond to the required ones. In this case, they need to be corrected in the source code of the program, recompiled in the Bascom AVR development environment, and loaded into the microcontroller memory instead of the Cooler-test.hex file attached to the article, the resulting HEX file. If the starting voltage of the fan motor is unknown, it can be determined experimentally. To do this, instead of the working program, you need to load the debug program developed by me into the memory of the microcontroller. The Cooler-test.hex file attached to the article contains its codes. The microcontroller configuration is programmed in the same way for the working and test programs in accordance with Fig. 6, which shows the AVRISP mkII programmer configuration setup window.

3 s after the power is turned on, the Cooler-test program starts controlling the fan, gradually increasing from 55 to 95 steps of 5 units the code that sets the duty cycle of the impulse voltage supplying the fan. This roughly corresponds to a change in the DC component of this voltage from three to five volts. The duration of each stage is 10 s, during which the fan and the HL1 LED are on, and a pause of 5 s, during which the fan is de-energized and the LED is off. The end of the program is signaled by a series of five short flashes of the LED. By observing the LED, it is easy to determine at what stage the fan started to rotate, and to determine the value of N1, which should be written to the main program. The operation of the device in emergency mode is checked by disconnecting the connector from the temperature sensor. In this case, the fan should turn on and operate at full power in intermittent mode (33 s - operation, 33 s - pause). LED HL1 should be lit. Its desired brightness is set by selecting resistor R3. Microcontroller programs can be downloaded at ftp://ftp.radio.ru/pub/2016/11/fan.zip. Author: A. Savchenko, pos. Zelenogradsky, Moscow region

Artificial leather for touch emulation

15.04.2024 Petgugu Global cat litter

15.04.2024 The attractiveness of caring men

14.04.2024

▪ Diesel smoke harms the heart and blood vessels

▪ section of the site Electrical safety, fire safety. Article selection ▪ Article Personal computer. History of invention and production ▪ article What is color blindness? Detailed answer ▪ article Organization of workflow on labor protection ▪ article Five-element YAGI at 20 meters. Encyclopedia of radio electronics and electrical engineering ▪ article Rope session (several tricks). Focus secret

Comments on the article: viktor With a short circuit, it will not turn off - the wiring will burn out. works under light load. Leonid Don't understand what's the point? the thyristor can actually turn the mass on and off. But when you install the diode, it is the ground, it remains on. and in order for this to work, you need to add a relay that will connect a diode to the system and apply voltage to the control electrode. Maybe I don’t understand something, who is more literate - explain a guest Leonid! The diode passes current in one direction, i.e. from the generator to the battery.

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

Leave your comment on this article:

Leave your comment on this article: