|

|

TOOLS AND MECHANISMS FOR AGRICULTURE

Mini truck. Drawing, description

Directory / Tools and mechanisms for agriculture What only cars and trucks have not been created by domestic designers and designers: from chic "grand-exit" limousines to "ascetic" sports buggies, from multi-ton heavy trucks to swift "gazelles". However, the machines for the economy, so to speak, servants - small and simple, reliable and inexpensive, something is not visible. Izhi, Muscovites, Zhiguli are adapted by designers for these purposes, converting them into pickups. But the price of cars remains the same as that of cars - not everyone can afford it, and not everyone dares to carry sand, bricks, soil and other similar goods in bulk on them. And they are not adapted for driving on country roads at low speeds. In this position, perhaps the cargo scooter "Ant" can help out, but it also has its drawbacks: air cooling of the engine, low power, the location of the steering wheel in the middle of the track, an open chain drive. The industry cannot or does not want to establish the production of such a machine for the economy, considering this niche, apparently, unpromising. But from my own experience I know that such a truck would be useful not only for summer residents, but also for rural residents who have a courtyard. The prototype of the truck and even its "donor" was a mini-tractor, which I made even before the start of the construction of the country house. Let me remind you, since there was no electricity on the site, this tractor was used by me not only (and not so much) for cultivating the land or as a tractor of a cargo cart, but as a drive for various construction units: a concrete mixer, a woodworking machine, etc. For this, the mini-tractor had a power take-off shaft. I considered it necessary to install the same shaft on the truck. The new machine inherited from a mini-tractor (the need for which had disappeared by that time, since electricity was still brought to the site) wheel gears, wheels (from a SZD motorized stroller), a gearbox (from a ZAZ-965 car) and a “breaking” frame with some modifications. It was this design that provided the truck with high maneuverability - it can turn around almost on the spot.

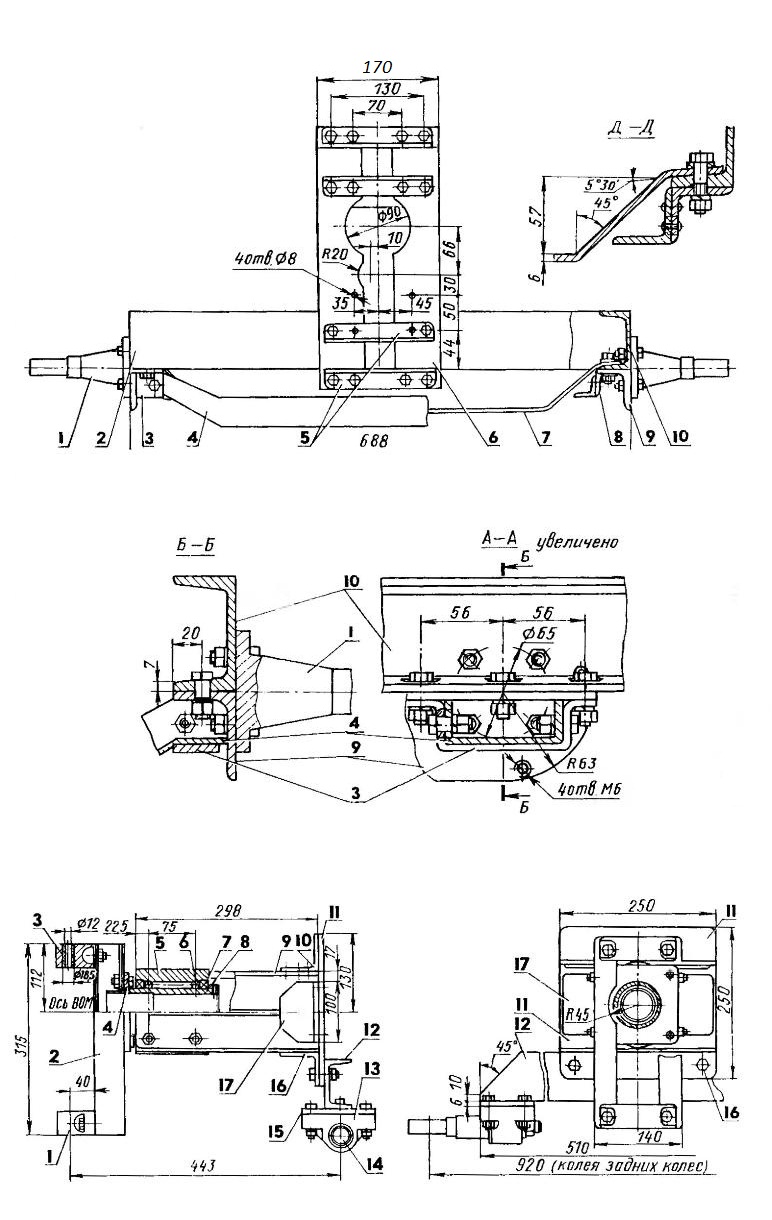

The front semi-frame has undergone the greatest modernization: it has become longer, wider, its cross member has now been made composite, and the beams diverged at an angle of 36 ° to the spars - so as not to interfere with the increased (up to 20 ° in each direction) "break" of the frame. Instead of under-engine brackets, a sub-engine platform made of 6-mm steel sheet was installed on it, and a curved beam from channel No. 8 was mounted between the axles, which significantly increased the rigidity of the structure. The spars were lengthened with extensions, each of which was made from a pair of pieces of steel corners No. 4, riveting them with shelves along the length, thus obtaining a profile in the shape of the letter Z. Only its rack with lugs remained intact in the front half-frame. The rear half-frame remained almost the same. I just replaced the rear axle beam with a longer one to widen the track and moved it behind the trim plate to increase the base of the truck. Calculations showed that this beam can also be made from one channel No. 8 (on a mini-tractor it was made from two of the same channels, without calculation). At the same time, there was still a significant margin of safety. The dimensions of the car were limited by the condition that it fit together with the Zhiguli in one standard garage measuring 6x3,2 m. Although the dimensions and design of the front half-frame have been significantly changed, the layout of the power unit and transmission - the engine with a gearbox and power take-off shaft, axle shafts with wheel gears - remained similar to that of the mini-tractor. On the extensions (extensions) of the spars, I mounted an open cabin with comfortable seats: for the driver - above the left wheel on the wing, and on the right wing - the passenger seat. Outside, on the front panel of the cab in its middle, he placed a radiator grill, and on the sides - headlights. On the rear half-frame I installed a spacious wooden body, and under it - a box for the battery. The engine of the truck with the loud name "Hercules" of American production, 2-cylinder, 4-stroke, with a cast-iron block and liquid cooling. got it on the occasion of a neighbor in the country, to whom he did not know how he got and lay idle for many years. The motor was not new, besides "defrosted" - with the cooling system jacket bursting at the top. He attracted me with his compactness. The Ulyanovsk UD-2, which stood on a mini-tractor, was almost twice as large in size, and its power was only 8 hp.

I revised Hercules - surprisingly, the parts had almost no wear and rust did not get to them. The crack on the shirt was sealed with VGO-ZO-1 sealant. A good sealant, withstands temperatures up to 250 ° C (although the coolant does not heat up to such a temperature), and now it has been tested by time - the tightness of the shirt has not been broken. The engine cooling system includes a fan with a casing, a centrifugal pump (pump) and a radiator - compact, but with an almost doubled heat output (compared to a conventional one of the same size). The fan and pump are driven from the crankshaft of the engine by a V-belt drive. To control the temperature of the coolant, a sensor is installed on the cylinder block, and a pointer on the dashboard. But the sensor and fuel level gauge were not even required. The gas tank - a translucent polyethylene canister - is located in plain sight, between the backs of the driver's and passenger's seats. Fuel (gasoline of the lowest quality) flows by gravity into the carburetor through a shut-off valve with a filter. Next to the fluid temperature sensor on the instrument panel is the ignition switch. The engine is started by a starter. The ignition system is from magneto. The headlights with high and low beams and the starter are powered by a battery. Light control - toggle switch on the dashboard. For the joint operation of the starter from the car "Zaporozhets" with the flywheel of "Hercules", on the latter, it was necessary to mount a ring gear from the Zaporozhye flywheel. Truck chassis - tractor type with rigid wheel suspension. All wheels of the same standard size - from the SZD motorized stroller. Leading and brake - front. Depreciation - due to pneumatics. The transmission consists of a clutch basket with a gearbox from a Zaporozhets car, axle shafts with elastic rubber clutches (the front driveshaft from a Zhiguli car) and improvised wheel reduction gears. The gearboxes, in addition to a significant decrease in the number of revolutions (i = 6,35), reverse the rotation of the axle shafts, since the gearbox on the truck is turned 180 ° relative to its position on the Zaporozhets. Rubber couplings compensate for the misalignment of the axle shafts with the shafts of the wheel gears. Brake discs are rigidly mounted (welded) on the input shafts of the gearboxes. To drive the power take-off shaft (PTO), I removed the top cover from the gearbox, and in its place I fixed the PTO engagement mechanism. The shaft itself is a cardan transmission of several "knees" with hinges. Its first "knee" is attached to the shaft of the switching mechanism by means of a key connection. In the place of the "break" of the frame, the PTO has a double hinge (from a pair of crosses). In the rear semi-frame, it passes through two bearing assemblies and has another "helicopter" hinge between them. At the very end of the last "knee" behind the trim plate, a flange is installed, to which the counter flange of the drive shaft of some unit or mechanism can be connected. The PTO rotation speed is controlled by the engine speed. The truck controls are classic: to the left of the steering column is the clutch pedal, to the right are the brake and gas pedals. The steering column and steering mechanism with a bipod are from the Moskvich car. The force for turning on the rear half-frame is transmitted by a system of rods, rocking chairs and levers. The last rod in the place of the "fracture" of the frame has a cross. Since the truck control pedals are located on the left side, and the carburetor throttle, clutch and right brake shoe control levers are on the right side, shafts with levers are used to transfer forces from the pedals from side to side. Further, the efforts on the actuators are transmitted again with the help of rods, levers and rocking chairs. For compactness, the clutch rod shaft is laid in a tubular brake shaft in plain bearings -. nylon bushings inserted into the ends of the pipe. A wooden body is placed on the rear half-frame. Its frame is made of bars with a section of 35x35 mm, plywood sheathing. For dumping loads, the body is hingedly mounted on a semi-frame - on an axis in two lugs, and the tailgate is made reclining. The body is raised by shifting the center of gravity of the load back. To prevent spontaneous lifting in the transport position, the body is additionally attached to the rear half-frame with two M10 screws. The maximum speed of the truck is just over 40 km/h. I think that for such a vehicle is quite enough. The power of the engine is enough to start off a loaded car even from 3rd gear, and an empty one from 4th. It is necessary to adapt to driving a truck - turning with the help of a "fracture" of the frame after driving a car is quite unusual. And although after the arrangement of the summer cottage, the need for a truck, in general, has disappeared, while I keep it together with the Zhiguli under the same roof. I can’t decide to disassemble for spare parts - the car turned out to be successful. Author: E.Evsikov

▪ Machine for manual transplantation

Machine for thinning flowers in gardens

02.05.2024 Advanced Infrared Microscope

02.05.2024 Air trap for insects

01.05.2024

▪ The brightest galaxy in the universe discovered ▪ Advanced design system Conventor SEMulator3D ▪ Intestinal parasites help you get pregnant ▪ Algorithm for Predicting Turbulent Flows in the Solar Atmosphere

▪ site section Low frequency amplifiers. Article selection ▪ article A bear stepped on his ear. Popular expression ▪ Chitauan article. Nature miracle

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

See other articles Section

See other articles Section