|

|

HISTORY OF TECHNOLOGY, TECHNOLOGY, OBJECTS AROUND US

Spinning machine. History of invention and production

Directory / The history of technology, technology, objects around us The eighteenth and nineteenth centuries were marked by an unprecedented technological upsurge. In the course of a hundred and fifty years, many brilliant inventions were made, new types of engines were created, new means of communication and transport were mastered, a wide variety of machine tools and machines were invented. In most branches of production, manual labor was almost completely replaced by machine labor. The speed, quality of processing and labor productivity have increased several dozen times. Thousands of large industrial enterprises appeared in the developed European countries, new social classes were formed - the bourgeoisie and the proletariat.

The industrial rise was accompanied by major social changes. As a result, Europe, and indeed the whole world, had changed beyond recognition by the end of the XNUMXth century; the life of people was no longer at all like the one that was at the beginning of the XNUMXth century. Perhaps for the first time in history, a technological revolution has so visibly and clearly affected all aspects of human life. Meanwhile, the beginning of this great machine revolution is associated with the creation of an automatic spinning machine - the very first machine that was widely used in production. It can be said that the spinning machine turned out to be the prototype of all subsequent machine tools and mechanisms, and therefore its invention, in its significance, went far beyond the narrow framework of textile and spinning. In a sense, her appearance symbolized the birth of the modern world.

Spinning in the form in which it was described above - with the help of a hand spindle and a spinning wheel - existed for several millennia and remained during all this time a rather complicated and time-consuming task. The spinner's hand, when making monotonous movements of pulling, twisting and winding the thread, quickly got tired, labor productivity was low. Therefore, a significant step in the development of spinning occurred with the invention of a hand spinning wheel, which first appeared in ancient Rome. In this uncomplicated device, the wheel a, during its rotation, rotated with the help of an endless cord a wheel of smaller dimensions d, on the axis of which a spindle b was put on. The process of spinning on a hand-held spinning wheel was as follows: the right hand, with the help of a handle, rotated the large wheel a, while the left hand, pulling a strand from a bundle of fibers, directed the thread either obliquely to the spindle (then it twisted and twisted) or under a straight line. angle (then it itself, being ready, wound on a spindle).

The next major event in the history of spinning was the appearance of the self-spinning wheel (circa 1530), the inventor of which is called the stonemason Jurgens from Braunschweig. His spinning wheel was set in motion by the legs and freed both hands of the worker for work. Work on a self-spinning wheel was as follows. The spindle 1 was tightly connected to the flyer 2 and received movement from the lower large wheel 4. The latter was connected to a block fixedly mounted on the spindle. Coil 3, at one end of which a block of smaller diameter was fixed, was freely put on the spindle. Both blocks were driven by the same wheel 4, but the spindle and flyer connected to the larger block rotated more slowly than the spool connected to the smaller block. Due to the fact that the coil rotated faster, the thread was wound on it, and the speed of the wound thread was equal to the difference between the speeds of the spindle and the coil. The spinner pulled the fibers out of the whorl with her hand and partially twisted them with her fingers. The thread before entering the flyer moved along the axis of the spindle. At the same time, it rotated, that is, twisted, and made completely the same number of revolutions as the spindle. After passing through flyer 2, the thread changed direction and went to the spool already at a right angle to the spindle axis. Thus, compared to a conventional spinning wheel, a self-spinning wheel allowed the thread to be pulled, twisted and wound at the same time.

From the spinning process, two operations were already mechanized here: twisting the thread and winding it on a spool, but the drawing of the fibers from the whorl and their partial twisting took place manually. This greatly slowed down the whole work. Meanwhile, in the first third of the XNUMXth century, an improved Kay loom was created, which made it possible to significantly increase the speed of weaving. On the new loom, the nimble weaver was able to weave as much yarn as six experienced spinners supplied. As a result, a disproportion arose between spinning and weaving. The weavers began to feel a shortage of yarn, as the spinners did not have time to prepare it in the right amount. Not only did yarn become very expensive, but it was often impossible to get it at all at any price. And the markets demanded more and more fabrics. Several generations of mechanics vainly puzzled over how to improve the spinning wheel. During the XNUMXth and first half of the XNUMXth centuries, several attempts were made to equip the self-spinning wheel with two spindles in order to increase its efficiency. But it was too hard to work on such a spinning wheel, so this idea did not spread. It was clear that spinning on several spindles at once would be possible only when the very operation of drawing the fibers was mechanized. This difficult task was partly solved by the English mechanic John White, who invented a special exhaust device in 1735. According to Marx, it was this part of the machine that determined the beginning of the industrial revolution. Lacking funds, White sold the rights to his remarkable invention to the entrepreneur Lewis Paul, who took out a patent for it in 1738. In Paul and White's machine, human fingers were first replaced by a pair of "pull" rollers rotating at different speeds. One roller had a smooth surface, while the other was rough with a corrugated surface or upholstered with tow. However, before entering the rollers of the machine, the cotton fibers had to be pre-treated - they had to be laid parallel to each other and pulled out. (This was called "combing" the cotton, or carding.)

Paul and White tried to mechanize this process and created a special carding machine. The principle of its operation was as follows. The cylinder, equipped with hooks over its entire surface, rotated in a groove, which was equipped with teeth on its inner side. The cotton fibers were passed between the cylinder and the trough and thus combed.

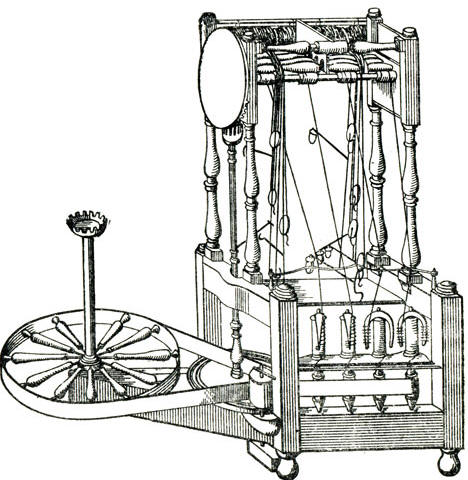

After that, the yarn in the form of a thin ribbon was fed into the spinning machine and here it was first drawn in the draft rollers, and then entered the spindle, which rotated faster than the rollers, and twisted into a thread. The first such spinning wheel was built by Paul in 1741. It was the first spinning machine in history. Improving their machine, Paul and White began to pass the yarn through several rollers. Rotating at different speeds, they pulled it into a thinner thread. From the last pair of rollers, the thread entered the spindle. In 1742, White built a machine that spun on 50 spindles at once and was driven by two donkeys. As subsequent events showed, the draft rollers he invented turned out to be an extremely successful innovation. But in general, his car was not widely used. It was too expensive and cumbersome for a lone artisan. An acute shortage of yarn continued to be felt in subsequent years. This problem was partly solved only after the creation of the Hargreaves spinning machine. Hargreaves was a weaver. His wife made yarn for him, and what she managed to spin in a day was not enough for him. Therefore, he thought a lot about how the work of the spinners could be accelerated. Chance came to his rescue. One day, Hargreaves' daughter, Jenny, accidentally knocked over a spinning wheel, but her wheel continued to spin, and the spindle continued to spin yarn, although it was in a vertical rather than horizontal position. Hargreaves immediately exploited this observation and built a machine in 1764 with eight vertical spindles and one wheel. He named the car "Jenny" after his daughter's name. She brought her creator neither money nor happiness. On the contrary, the invention of Hargreaves caused an uproar among the spinners - they foresaw that the machine would put them out of work. A gang of excited people broke into Hargreaves' house one day and destroyed the car. The inventor himself and his wife barely escaped reprisal. But this, of course, could not stop the spread of machine spinning - just a few years later, "Jenny" was used by thousands of craftsmen.

Like White's machine, "Jenny" required pre-treatment of cotton fibers. The dressing of the thread took place here from a ribbon of combed cotton. The cobs with the roving were placed on an inclined frame (the slope served to facilitate the winding of the roving). Instead of White's draft rollers, Hargreaves used a special press consisting of two blocks of wood. The threads of the roving from the cobs passed through a draft press and were attached to the spindles. The spindles, on which the finished thread was wound, were on a fixed frame on the left side of the machine. At the bottom of each spindle there was a block, around which there was a drive cord thrown over the drum. This drum was located in front of all blocks and spindles and was driven by a large wheel rotated by hand. Thus, the big wheel turned all the spindles. The spinner moved the carriage of the drawing press with one hand, and with the other turned the wheel that set the spindles in motion. The operation of the machine consisted of the following processes: the press was closed and retracted from the spindles - as a result, the thread was pulled out. At the same time, the spinner turned the wheel, it set the spindles in motion, and they twisted the thread. At the end of the withdrawal, the carriage stopped, and the spindles continued to rotate, making additional twisting. After that, the carriage was fed back to the spindles, all the threads were slightly bent with a special wire so that they got into the winding position. During the return stroke of the carriage with an open press, the threads were wound around the spindles due to the rotation of the latter. The Hargreaves pull press essentially replaced the worker's hand. The whole work was reduced basically to three movements: to the rotation of the drive wheel, to the rectilinear movement of the carriage back and forth, and to the bending of the wire. In other words, man played only the role of a driving force, and therefore, in the future, it became possible to replace the worker with other, more permanent and powerful sources of energy. The remarkable significance of Hargreaves' invention was that it made possible the maintenance of several spindles by one worker. His very first machine had only eight spindles. Then he increased their number to 16. But even during the life of Hargreaves, "Jenny" machines appeared with 80 spindles. These machines could no longer be powered by a worker, and they began to be connected to a water engine. Due to the simplicity of design and low cost, as well as the ability to use a manual drive, "Jenny" has become widespread. By the 90s of the 20th century, there were already more than XNUMX thousand "Jenny" spinning wheels in England. Most of them belonged to single weavers. The smallest of them did the work of six or eight workers. It was the first machine in history to be mass-produced. The Hargreaves machine helped to some extent to overcome the spinning famine and contributed to a powerful rise in production in England, but it was still not quite what was required. The "Jenny" exhaust device proved to be imperfect. Due to insufficient drawing, the yarn turned out to be thin, but weak. For greater strength of the fabric, weavers had to add linen thread to the yarn. A more successful machine was soon created by Arkwright. It was a combination of White's exhaust mechanism with the twisting and winding apparatus of Jurgens' self-spinning wheel. By profession, Arkwright was a barber in Bolton, England. Most of his clients were small-scale spinners and weavers. One day, Arkwright witnessed the weavers talking about the fact that the linen was woven from linen threads interspersed with cotton threads, since the Hargreaves machine was not able to supply much yarn and its threads did not have sufficient strength. Shortly thereafter, Arkwright got himself a Jenny machine, studied it, and became convinced that he could build another that would spin faster and finer. He got down to business, and indeed, he managed to build a spinning wheel that completely automatically performed all the processes. The spinner had only to ensure that enough material was fed into the machine and to connect the broken threads.

The work on the Arkwright machine proceeded as follows. The drive wheel rotated the spindles with flyers. The roving, pre-made from cotton, was placed on cobs, which were placed on a horizontal shaft at the top of the loom. The roving ribbon of cotton fibers entered the draft rollers located in front of the cobs. In each pair, the lower roller was wooden, corrugated, and the upper one was covered with leather. Each subsequent pair of rollers rotated faster than the previous one. The upper rollers were pressed against the lower ones by weights. The elongated thread came out of the last pair of rollers, passed through the hooks of the flyer and wound around the spindle. In order to get the lag of the coils sitting on the spindles from the flyers, the coils were somewhat delayed by a cord passing through the grooves of the pulleys at the bottom of each coil. As a result, threads of such a strength were obtained that from now on it was possible to make fabrics from pure cotton, without any admixture of linen. In the described machine, the principle of continuity of work was fully implemented, so it was called a water machine. Arkwright turned out to be not only a successful inventor, but also a clever businessman. In a community with two merchants, he built his own spinning mill, and in 1771 he opened a second factory in Cromford, where all the machines were driven by a water wheel. Soon the factory grew to the size of a large enterprise. In 1779 it had several thousand spindles and employed 300 workers. Without stopping there, Arkwright founded several more factories in different parts of England. In 1782, he already employed 5000 workers, and his capital was estimated at 200 thousand pounds sterling. Arkwright continued to work on new machines that would mechanize the entire yarn processing process. In 1775, he received a patent for several auxiliary mechanisms at once. The main ones were: a carding machine, a movable comb, a roving machine and a feeding device. The carding machine consisted of three drums and served for combing cotton. (This was an improvement on White's machine.) The movable comb was used as an addition to the carding machine - it was used to remove the carded cotton from the drums. The roving machine turned the combed cotton into a cylindrical roving ready for processing on the spinning machine. The feeder was a movable web that delivered cotton to the carding machine for processing. In subsequent years, Arkwright's fame was overshadowed by accusations of stealing other people's inventions. A number of lawsuits have shown that all the machines he patented were not actually invented by him. So, it turned out that the spinning water machine was invented by the watchmaker John Kay, the card machine was invented by Daniel Born, the power device was invented by John Lees. In 1785, all of Arkwright's patents were cancelled, but by this time he had already become one of the richest English manufacturers. In 1772, the mechanic Wood creates a machine where the exhaust device is stationary, and the spindles move, i.e., a process occurs that is the opposite of that which takes place in the Hargreaves machine. Here the tape, which is the object of labor, occupies a passive position, and the spindle (working tool) is activated to a large extent. The drawing press, remaining stationary, closes and opens, and the spindles not only rotate, but also move.

The last point in the creation of a universal spinning machine was put by the weaver Samuel Crompton, who created the so-called mules. It combined the principles of the "Jenny" and Arkwright's water machine.

Instead of the Hargreaves press, Crompton used draw rollers. In addition, a carriage was introduced that moved back and forth. Spindles were placed on the carriage. When the carriage with the spindles moved away from the rollers, the spindles pulled out even more and twisted the thread. When the carriage approached the rollers, the thread twisted and wound around the spindle. Whereas the water machine made strong but coarse yarn, and the Jenny made fine but weak yarn, Crompton's mules produced strong yet fine yarn. Author: Ryzhov K.V.

▪ Frisbee

Artificial leather for touch emulation

15.04.2024 Petgugu Global cat litter

15.04.2024 The attractiveness of caring men

14.04.2024

▪ Smart bracelet will track the composition of sweat ▪ Language influences thinking from infancy ▪ Silicon shortage for solar energy

▪ site section Electric motors. Article selection ▪ article Chaplygin Sergei. Biography of a scientist ▪ article When were the first animal protection laws passed? Detailed answer ▪ article Wind turbine. Personal transport ▪ article This complicated Ohm's law. Encyclopedia of radio electronics and electrical engineering ▪ article Tone register. Encyclopedia of radio electronics and electrical engineering

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

See other articles Section

See other articles Section