|

|

ENCYCLOPEDIA OF RADIO ELECTRONICS AND ELECTRICAL ENGINEERING Acoustic system VERNA 50A. Encyclopedia of radio electronics and electrical engineering

Encyclopedia of radio electronics and electrical engineering / Speakers Readers are offered a description of another acoustic system by our regular author A. Demyanov. It is made on the basis of domestic loudspeaker heads: 25GDN-3-4, 5GDSH-5-4 and 6GDV-4-8 and has good technical characteristics. So, thanks to the panels of "soft" acoustic impedance (PMAS) installed in the woofer compartment of the loudspeakers, it was possible to significantly improve the reproduction of lower sound frequencies, and the refinement of the midrange head according to the method of V. Shorov made it possible to obtain a light and clear sound. Despite the wide choice of speakers on the Russian market, this did not reduce the interest in their independent production. The main reasons for this phenomenon, according to the author, are the dissatisfaction of sound recording enthusiasts with the real sound quality of foreign-made speakers, especially in the middle price category; a poor choice of domestic industrial systems, and their rather high cost. The main thing is the desire of radio amateur designers to build an AU, designed to work in a particular room and as part of the sound amplifying path available to the listener. A huge market of component parts also contributes to independent creativity: loudspeaker heads, finishing materials, all kinds of accessories, etc. An important role, of course, is played by the fact that a speaker created on its own will cost its creator two to three times cheaper than an industrial one. When developing the proposed design of a home-made speaker, the task was to create it on the basis of domestic loudspeaker heads that are constantly on sale and well known to a wide range of consumers. As a result, the AS "VERNA 50A" was developed (Fig. 1), designed to be installed on stands 40 ... 50 cm high. With its help, you can sound a room up to 25 m2 and play a wide variety of musical works.

Its technical characteristics: nominal electrical resistance - 8 ohms; nominal range of reproducible frequencies - 50 ... 20 Hz with a frequency response unevenness of 000%: level of characteristic sensitivity - 2 dB / W / m; nominal (maximum noise) power - 85.5 (50) W; dimensions - 75x215x315 mm; weight of one AC loudspeaker - 600 kg. Each AC loudspeaker is a three-way phase inverter with two woofers 25GDN-3-4. located in the lower compartment with a volume of 17 dm3, medium-frequency head 5GDSh-5-4. placed in a special box, and HF head 6GDV-4-8. installed at the top of the case. The front panel of the loudspeaker (Fig. 2) is made of solid birch and is 40 mm thick. Its shape and location of the heads on it are chosen taking into account their real electro-acoustic characteristics and directivity patterns in the frequency range of 300...20 Hz.

The remaining panels of the loudspeaker housing (Fig. 3) are two-layer: on the inside - chipboard 16 mm thick, on the outside - furniture plywood 15 mm thick.

When gluing with PVA-E glue, these materials were kept under load (about 120 kg) for three days. This helped to obtain panels with a damping factor of about 0.9 and good damping properties. In the side panels, a part of the chipboard layer is cut out (Fig. 4), which is necessary for the unhindered installation of the plates that form the phase inverter passages.

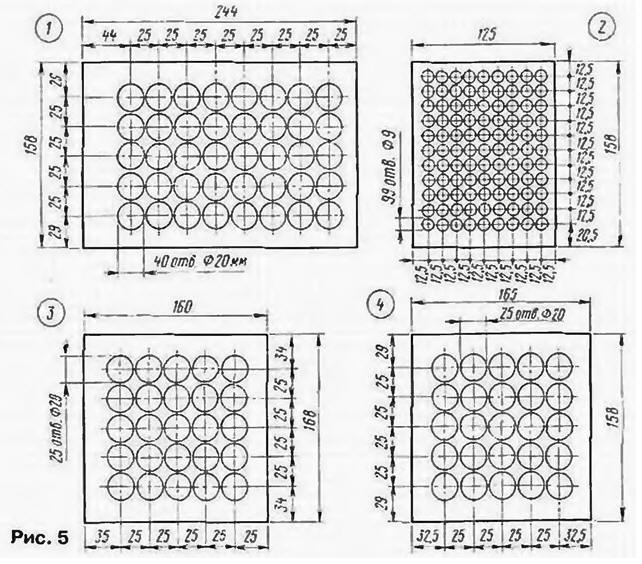

As can be seen from fig. 3, at the joints of the panels have a selected "quarter", which provides maximum vibration damping and the necessary rigidity of the loudspeaker case. Its weight without heads and filter board is 20 kg. It should be noted that the use of a powerful front panel and a two-layer construction of the rest of the materials with different damping ratios is not accidental. The thing is. that with small sizes of low-frequency heads, their large mass (2 kg) and a resonant frequency of 50 Hz, it is possible to obtain good sounding of low sound frequencies only with careful damping of the acoustic design. This is exactly what was implemented, taking into account the above design features of the AC loudspeaker enclosure. Its walls do not vibrate even during the playback of a musical signal with a high content of low-frequency components with a power of up to 70 watts. The loudspeaker heads are fixed in the recesses of the front panel of the case. The low-frequency heads are mounted on damping sealing rings made of natural felt 8 mm thick, and the mid-frequency and high-frequency heads are mounted on rings made of felt 6 and 3 mm thick, respectively. Additional rigidity of the loudspeaker of the speaker cabinet. and hence, its greater damping is provided by panels of "soft" acoustic resistance 1 - 4 (see Fig. 3 and Fig. 5). All of them are made of plywood and glued into the body. The number and area of holes in the panels were determined empirically. The panels dampen the main resonant frequencies of the woofers and reduce the displacement amplitude of their diffusers, as a result of which non-linear distortions are reduced and the linearity of the frequency response in the region of 45 ... 600 Hz is improved.

To achieve the monolithic design of the AC loudspeakers, 30 (on each side) oak dowels with a diameter of 8 and a length of 50 mm are inserted into the ends of their front panels (not shown in Fig. 3). The same dowels are installed in the ends of the upper, lower and rear panels, respectively 13. 13 and 30 pieces. All of them are fixed with glue. The ends of all perforated panels are also reinforced with dowels 6 mm in diameter and 40 mm long. The 5GDSh-5-4 mid-frequency driver is installed in a standard industrial plastic box with an internal volume of 2.8 dm3 (Fig. 6).

The box is attached to the inner surface of the front panel with four screws fixed with epoxy glue. Inside the midrange box is pasted over with natural soft felt 12 mm thick. About 1 dm3 of the box volume is filled with cotton batting weighing 120 g, and the rest of it is filled with cotton wool at the rate of 100 g/dm3. Such sound damping almost completely eliminated the influence of internal resonances on the midrange head cone and ensured the uneven frequency response of the speakers in the range of 500 ... 5000 Hz no more than ±2 dB. The passages (slots) of the phase inverters are formed by the side panels of the housing (Fig. 6) and metal plates made of D16T aluminum alloy (Fig. 7).

The plates are fastened with screws to a wooden block (Fig. 8) which is glued to the front panel of the loudspeaker housing. The variable section of the passage prevents the occurrence of standing waves and. as a result, it prevents the appearance of mumbling during the operation of the phase inverter. Hole areas and penetration depth are set to 47 Hz. The location of the phase inverter slots along the edges of the front panel helps to reduce the reflections of sound waves from its surface.

From the inside, the loudspeaker case is pasted over with soft natural felt 17 mm thick. on top of which are glued rollers of cotton batting with a diameter of 50 and a length of 150 mm. The inner surface of the front panel is pre-filled with a mixture of PVA-E glue with beech sawdust, the thickness of the dried layer is 5 mm. On the lower and upper edges of the back panel, beech triangular corner bars with a side of 30 mm are glued. The same bar is installed between the bottom and front panels. The bars relieve longitudinal stresses that occur when the case is deformed and when speakers are installed on insufficiently massive and rigid stands. The outer surface of the front panel of each loudspeaker is tinted "mahogany", and the rest are finished with mahogany veneer. The front panel has a removable frame covered with an acoustically transparent fabric. Schematic diagram of separation filters is given. in fig. 9. LF and MF heads are included through the filters L1R1C1 (6 dB / oct) and R2C2-C6L2 (6 dB / oct), respectively, and the tweeter - through the filter (18 dB / oct) R3C7C8L3C9-C11. The filter parts are placed on a 10 mm thick plywood board with dimensions of 100-55 mm. The installation was carried out without the use of connecting wires, their functions are performed by the conclusions of the parts. When assembling, resistors were used: PEV-8 (R1) and S5-16MV-5V (R2. R3). All capacitors K73-16 for operating voltage 63 (CI, C2) and 160 V (others). Coil L1 is wound on a magnetic circuit measuring 8x15x85 mm from 2000NM ferrite. Its winding consists of 240 turns of wire PEL-1 1.12. Winding coil to coil in three layers. The windings of the coils L2, L3 are placed on cylindrical frames of industrial production with a diameter of 18 and a height of 20 mm. The first of them contains 212. and the second - 120 turns of wire PEL-1 0.56. The windings of the finished coils are impregnated with BF-4 glue and tied with PVC tape. The crossover filter board is installed at the bottom of the rear panel of the loudspeaker box. In the immediate vicinity of it there is a panel with clamps for connecting the loudspeaker to the power amplifier. To connect filters with midrange and bass heads and input jacks, two stranded (17 cores) silver-plated wires with a cross-sectional area of 1,8 mm (Fig. 9) in fluoroplastic insulation were used.

For loudspeakers, the main specifications have been carefully checked: nominal DC resistance, fundamental resonance frequency, characteristic sensitivity level and electrical impedance modulus in the reproducible frequency range. The verification was carried out in accordance with GOST 16122 - 67 "Loudspeakers. Methods of electroacoustic testing" [1]. The woofers selected for operation in AC loudspeakers had a DC resistance of 3,53 (two) and 3,58 (two) ohms, fundamental resonance frequencies of 47 (two) and 50 (two) Hz, and a characteristic sensitivity level of 85.4 dB / W / m . Specimens with voice coil resistances of 3,68 and 3,66 ohms were taken as midrange heads. with fundamental resonant frequencies of 173 and 171 Hz and a characteristic sensitivity level of 92 dB/W/m. Midrange heads were modified according to the method proposed by V. Shoroey [2]. involving the impregnation of their diffusers with gerlen-based mastic and the installation of PAS diffuser holders on the windows. consisting of two or three layers of synthetic material, made in accordance with TU 17 of the RSFSR 35-3941 - 81. The HF heads selected for the AC had a DC resistance of 6,24 and 6,3 ohms. the main resonant frequencies are 2510 and 2530 Hz. characteristic sensitivity 92 dB/W/m. The HF heads have also undergone a slight revision. To do this, they were dismantled, the voice coils were re-centered, and the amount of sound absorber inside their domes was tripled. The following measuring equipment was used for measurements and tuning: sound generator GZ-34. universal voltmeter V7-26. oscilloscope C1 -91. high-frequency meter E7-9. multimeter F4800. as well as reference inductors and capacitors. When self-manufacturing the structure, the following assembly sequence should be followed. First, choose your materials carefully. Treat surfaces to be glued with coarse-grained emery paper. Glue PVA-9 is used for gluing two-layer body panels. In other cases, a mixture of PVA-E and fine chipboard (beech, oak) sawdust in a ratio of 10:3 is used as an adhesive. Then, from the prepared panels, you should assemble the frame - without the front and back panels and fix its "straight" corners with the help of metal corners and clamps - until the adhesive mixture dries completely (two to three days). Further, in accordance with Fig. 3 glue triangular cross-section bars into the frame. After a day, install wooden dowels with a diameter of 20 and a length of 25 mm into the torns of the upper and lower panels with a pitch of 8 mm on glue. Now, according to the actual external and internal dimensions, you need to make the front and rear panels (see Fig. 2 and 3). On the inner surface of the front panel, along the output holes of the phase inverters. install the plates (Fig. 7) attached with screws to the bars (Fig. 8). After that, the MF box is fixed with screws from the inside of the front panel of the loudspeaker case. Then, with the help of glue, the front panel is installed in its place in the frame and kept for four days under a load of 50 ... 100 kg. After that, wooden dowels are inserted into the ends of the front panel. Inside the case, according to Fig. 3, glue the PMAS panels (Fig. 5) and keep them for two or three days. In this case, panel 1 (see Fig. 5) is installed at the end of the body assembly, i.e. after the rear panel is installed. On the side panels, along the curved part of the bass reflex plates. 12 mm thick plywood panels are glued close to them with epoxy glue so that passages form. The woofer compartments of the loudspeakers are pasted over with soft natural felt 17 mm thick. Rollers made of cotton batting 40 mm in diameter and 100 mm long are glued into all their corners. In order to avoid overdamping, batting rollers are not installed near the input of phase inverters closer than 60 ... 70 mm. And the last. To maintain the value of the characteristic sensitivity, it is recommended to use a stranded wire with a large cross section to connect the speakers to the amplifier. For subjective listening to the speakers, the PIONEER PDS502 and DENON 1015m CD players and the PIONEER PL640 vinyl record player were used as signal sources. In addition to assessing the sound of AC "VERNA 50A", it was compared with the sound of speakers of medium and above average cost groups: "Status S50" by AR (USA) and "AE 520" by Acoustic Energy (England). Listeners were offered phonograph records with recordings of classical music by Russian and foreign composers ("All-Night Vigil" by S. Rachmaninov, "Scheherazade" by Rimsky-Korsakov, "Twenty-Four Caprices" by N. Paganini) and CDs with pop recordings ("Cadavrexguis" - Amanda Lear, "Na Na Hey Hey" - Donna Summer, a collection of "All That Jazz"), as well as national Japanese, Indian and Chinese music ("Tai Chi Too", "Shaman", "Seven Times Seven" - Oliver Shanti). Listening was carried out in several stages over four days. There were lovers of sound recording with great experience, speakers developers. students of the Moscow Conservatory. All listeners noted the clear, undistorted sound of AC 'VERNA 50A "at minimum (1 ... 4 W) and medium (20 ... 30 W) power. None of the experts experienced fatigue, even with prolonged listening, while the sound of AC "Status S50" and "AE 520" began to tire them after 20 ... 30 minutes. Literature

Author: A. Demyanov

Artificial leather for touch emulation

15.04.2024 Petgugu Global cat litter

15.04.2024 The attractiveness of caring men

14.04.2024

▪ Graphene laser for photonic microcircuits ▪ Toyota Mirai hydrogen sedan billboards purify the air ▪ brain-controlled hearing aid ▪ Safe genetically modified mosquitoes ▪ Hexgears Hyeku F2 Mechanical Keyboard

▪ section of the site Cultivated and wild plants. Article selection ▪ article Through the stump-deck (to bring down). Popular expression ▪ article When were traditional myths and legends first written down? Detailed answer ▪ oil tree article. Legends, cultivation, methods of application ▪ article Drying of electrical machines. Encyclopedia of radio electronics and electrical engineering ▪ article Sustainable postcard. Focus secret

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

Leave your comment on this article:

Leave your comment on this article: