|

|

ENCYCLOPEDIA OF RADIO ELECTRONICS AND ELECTRICAL ENGINEERING Switching laboratory power supply 0-30 volts, 0,01-5 amperes. Encyclopedia of radio electronics and electrical engineering

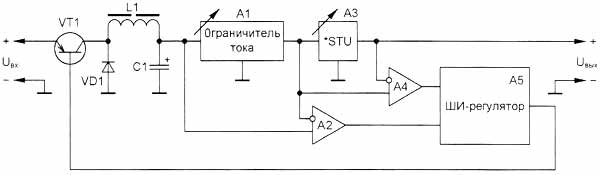

Encyclopedia of radio electronics and electrical engineering / Power Supplies The proposed device stabilizes the load supply voltage and limits the current consumed by it, switching to the current stabilization mode. The pulse mode of operation provides high efficiency in any operating modes. The device is not afraid of continuous output short circuits. It can serve as a current source for electrolysis, electroforming and other processes that require a stable or limited current. The device can be used to charge almost all types of batteries. Numerous descriptions of laboratory power supplies have been published in amateur radio literature. The proposed source is characterized by wide functionality, simplicity, high efficiency. On fig. 1 shows its functional diagram.

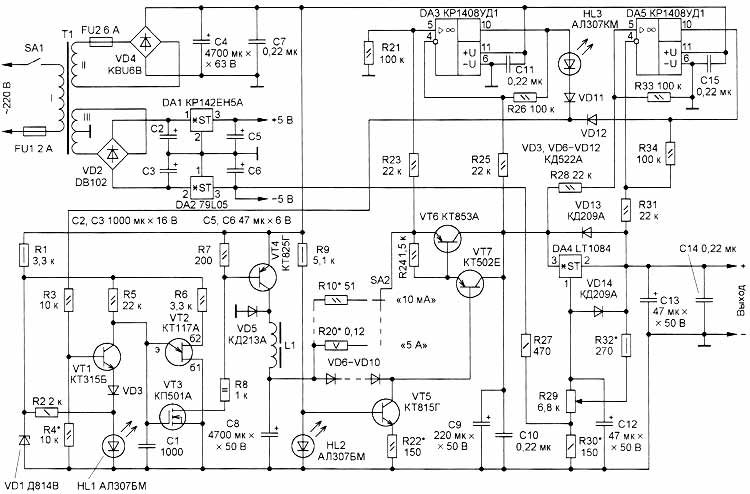

The basis of the device is a step-down voltage regulator with pulse-width regulation on a switching transistor VT1. After the storage elements - the choke L1 and the capacitor C1 - the sequentially adjustable linear current limiter A1 and the voltage regulator A3 are connected. The diode VD1 ensures the flow of the inductor current L1 into the capacitor C1 and the load when the switching transistor VT1 is closed. The load current is limited from above by node A1 from 10 mA to 5 A. The voltage regulator A3 allows you to adjust the output voltage from 0 to 30 V. Differential amplifiers A2 and A4 with a gain of about 5 control the voltage drop on the blocks A1 and A3. When at least one of them is too large, the switching transistor VT1 closes at the signal of the pulse-width controller A5. This achieves high efficiency and stabilization of not only the output voltage, but also the current. A small power dissipation on the control elements increases the reliability of the device, reduces its weight and dimensions by reducing the size of heat sinks compared to linear regulation. On fig. 2 shows a schematic diagram of the device. Components VT4, VD5, L1, C8 correspond to VT1, VD1, L1, C1 in fig. 1. On the elements VT1-VT3, C1, VD3, HL1, R3-R8, a pulse-width controller A5 is assembled. Current limiter A1 is assembled according to the current stabilizer circuit on transistors VT6 and VT7, diodes VD6-VD10 and resistors R10-R20, one of which is connected by switch SA2. The adjustable voltage regulator A3 is assembled on the DA4 chip. Differential amplifier A2 (see Fig. 1) - high-voltage op-amp KR1408UD1 (DA3) with resistors R21, R23, R25, R26. A similar differential amplifier A4 - DA5, R28, R31.R33, R34. The mains voltage from winding II, reduced to 30 V by transformer T1, rectifies the diode bridge VD4 and smoothes capacitor C4. This voltage (about 40 V) is the input for the switching regulator. Resistor R1 and zener diode VD1 form a parametric voltage regulator for the supply voltage of the master oscillator, made on a unijunction transistor VT2. Transistor VT3 - current amplifier master oscillator. The choice of the KT825G transistor as a switching transistor (VT4) is due to its high reliability and wide availability. The generation frequency of 40 kHz was chosen in accordance with the frequency properties of the KT825G transistor. A parametric voltage regulator of about 2 V is assembled on resistor R1 and LED HL2 to fix the voltage level at the emitter of the regulating transistor VT1. Diode VD3 prevents the reverse voltage from being applied to the emitter junction of this transistor. Opening, the switching transistor VT4 connects the inductor L1 to the output of the rectifier on the diode bridge VD4. The current flowing through the inductor L1 charges the storage capacitor C8. By changing the voltage at the base of the transistor VT1, you can adjust the width of the pulses that open the transistor VT4, and, accordingly, the voltage across the storage capacitor C8. The current limiter A1 is made on discrete elements. The refusal to use the LT1084 chip is due to its insufficiently high maximum input voltage (37 V). In addition, the use of discrete elements increases the efficiency. The voltage drop across the current-setting resistor of the integral stabilizer is 1,25 V; at a current of 5 A, a power of 6,25 W is dissipated on this resistor. In the applied current limiter, the voltage drop across the current-setting resistor UR is equal to the difference between the voltage drop across the diode circuit VD6-VD10 and the base-emitter voltage of the composite transistor VT6VT7. In this case, UR is approximately equal to 0,6 V. The power dissipated by the resistor R20 (at the limit of 5 A) is approximately equal to 3 watts. The resistance of the current-setting resistor R is calculated by the formula R=UR/I, where I is the required limiting current. The author's copy implements 11 current limit limits: 10, 50, 100, 250, 500, 750 mA; 1, 2, 3, 4, 5 A. Resistors R10-R20 correspond to them. Since the voltage across the capacitor C8 varies over a wide range, the current through the stabistor, made up of diodes VD6-VD10, determines the stabilizer on the VT5 transistor and the HL2 LED. Resistor R22 in the emitter circuit of the transistor VT5 sets the current through the VD6-VD10 circuit within 10 ... 12 mA. The adjustable voltage regulator A3 is made on the DA4 chip. Diodes VD13, VD14 help to increase its reliability. Through these diodes, when the power supply is disconnected from the network, capacitors C12 and C13 are discharged, eliminating the self-excitation of the stabilizer. To obtain a zero output voltage, a negative polarity voltage from the stabilizer DA27 is applied to the control electrode circuit through the divider R30R2. The rectifier on the diode bridge VD2 and integrated stabilizers DA1, DA2 also feeds a digital voltmeter on the KR572PV2A chip, assembled according to a typical circuit. The output signals of the operational amplifiers DA3 and DA5 through the diodes VD11 and VD12 are fed to a common load - a resistor divider R3R4. The HL3 LED is displayed on the front panel and signals the transition of the power supply to the current stabilization limitation mode. An increase in the voltage drop across the current limiter or voltage regulator causes a rise in voltage across resistor R4. When it exceeds the threshold value (about 3 V), transistor VT1 opens, shortening the generator pulses on transistor VT2. Construction and details The power supply is mounted in a housing with dimensions of 90x170x270 mm. Transistor VT4 and diode VD5 are installed without insulating spacers on one heat sink with an area of 200 cm2. A VT400 transistor (through an insulating gasket) and a DA2 stabilizer are mounted on a heat sink with an area of 6 cm4. To increase the temperature stability, it is advisable to install the VD6-VD10 diodes on the heat sink as close as possible to the VT6 transistor. The device is assembled on a universal breadboard, the printed circuit board has not been designed. Transformer T1 is made from the mains transformer of a tube TV. The magnetic circuit is dismantled, the coils are removed. The filament windings are wound up (they are located in the upper layer and are wound with a wire of the largest diameter), counting the turns. Multiplying this number of turns by 5, we get the number of turns of winding II. Next, the anode windings are completely wound from both coils onto one spool. Then half the number of turns of winding II is wound on each coil in bulk into two wires of the anode winding. Anode winding wire diameter of 0,8 mm corresponds to a cross section of 0,5 mm2. Winding in two wires gives an equivalent cross section of 1 mm2, which makes it possible to obtain a load current of 5 A. Multiplying the number of turns of the filament winding by 3, we obtain the number of turns of winding III. This winding can also be wound in two wires on one of the two coils. Due to the low current consumption from winding III, the asymmetry of the magnetic field of the transformer turns out to be insignificant. After assembling the magnetic circuit, the half-windings III are connected in series, taking into account the phasing, the beginning of one half-winding III is connected to the end of the other, forming a tap from the middle. The inductor L1 is wound on a B48 magnetic circuit made of 1500NM1 ferrite in bulk into two wires of the anode winding until the frame is filled. To create a non-magnetic gap between the cups, a textolite washer 1 mm thick was inserted. After tightening with the Mb bolt, the finished throttle is impregnated with BF-2 glue. Drying and polymerization of the glue were carried out in an oven at a temperature of 100 °C. When making an independent inductor on another magnetic circuit, it should be borne in mind that the current through the inductor has a triangular shape. The average current consumption of 5 A corresponds to an amplitude of 10 A, while the current of the magnetic circuit should not enter saturation. Stabilizer LT1084 (DA4) can be replaced by a domestic analogue KR142EN22A. Variable resistor R29 for greater durability used wire PPB. Given that a significant current flows through the SA2 switch, a 11P3N ceramic plate switch is used to increase stability and durability, its contacts are connected in parallel. LEDAL307KM (HL3) can be replaced by foreign L-543SRC-E. Establishment By selecting the resistor R30, a zero output voltage is set at the output of the power supply at the lower position of the variable resistor R29 engine according to the diagram, and by selecting the resistor R32 - a voltage of 30 V at the upper position of the R29 engine according to the diagram. A voltmeter is connected to terminals 2 and 3 of the DA4 stabilizer and a voltage of 4 V is set by selecting resistor R1,5. Trimmer resistors can be used for the time of adjustment. But their use for permanent operation is not recommended due to the instability of the resistance of the movable contact system. Then the load is connected to the output terminals through an ammeter. By changing the output voltage with the resistor R29, the output parameters are controlled by the ammeter and the built-in voltmeter. At low-current limits, due to the presence of control currents of the DA4 stabilizer, it will be necessary to adjust the resistance of the resistors R10-R12 compared to the calculated one. By turning on the HL3 LED, it is necessary to check the current limit and its stability at all limits. The proposed laboratory power supply is very convenient in operation, including for charging accumulators and batteries - from 7D-0.1 to starter automobiles. The final charging voltage is set using the built-in digital voltmeter, the required charging current is selected with the SA2 switch and the battery (battery) is connected. Charging is carried out with a stable current, when the specified voltage on the battery is reached, charging stops. During the three years of operation of the proposed device, there were no failures in its operation. Author: K. Moroz, Nadym, Yamalo-Nenets ed. districts; Publication: cxem.net

Machine for thinning flowers in gardens

02.05.2024 Advanced Infrared Microscope

02.05.2024 Air trap for insects

01.05.2024

▪ New series of operational amplifiers TSH80-81-82 ▪ Logitech Pop smart home controller ▪ Sony WF-XB700 and WH-CH710N Wireless Headphones ▪ Memory Samsung DRAM CXL 2.0 128 GB

▪ section of the site For a beginner radio amateur. Article selection ▪ article Theater begins with a hanger. Popular expression ▪ Article Courier. Job description

Comments on the article: Yura Hi all. Guys tell me the diagram of the power supply from the transformer: input 220, output 110 and 54 V. If there is one.

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

Leave your comment on this article:

Leave your comment on this article: