|

|

ENCYCLOPEDIA OF RADIO ELECTRONICS AND ELECTRICAL ENGINEERING Refrigerator machine. Encyclopedia of radio electronics and electrical engineering

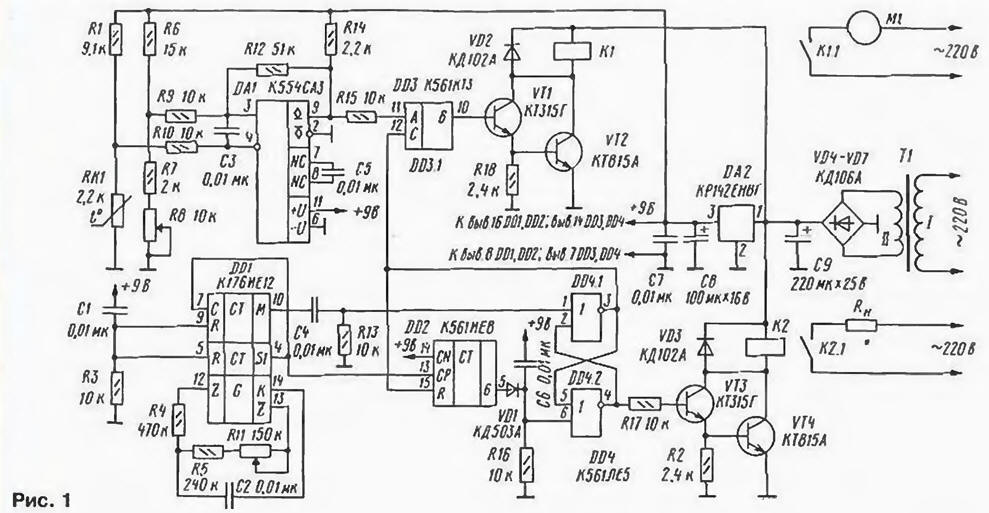

Encyclopedia of radio electronics and electrical engineering / Home, household, hobby It is known that even a small layer of ice on the evaporator of the refrigerator significantly impairs its operation. Therefore, it is recommended to turn on the defroster as often as possible. It has been experimentally established that for commercial refrigeration units, the operating mode can be considered optimal, in which 2 ... 3 hours are cooled and 10 ... 20 minutes are defrosted. It is this mode that provides the device offered to the attention of readers. It can also be used in household refrigerators with separate switching on of the compressor and the heating element of the defroster. The electronic device for automatic control of the temperature mode of the refrigerator operation consists of a temperature control [1] and a time setting [2] units. The first of them measures the temperature in the refrigerator chamber and maintains it within the limits set by the regulator, and the second - periodically every 2...3 hours for 10...20 minutes turns on the heating element of the hoarfrost thawer. A schematic diagram of the temperature control device of the refrigerator is shown in fig. 1. The temperature control unit consists of a comparator on a DA1 chip, a measuring bridge R1, R6 - R8, RK1, a thermostat blocking device on a DD3 chip, a current amplifier on transistors VT1, VT2 and an electromagnetic relay K1, which turns on the refrigerator compressor motor. Thermistor RK1 performs the functions of a temperature sensor. During the operation of the thermostat, the voltages on the shoulders of the measuring bridge are compared. The signal that appears on its diagonal is fed to the inputs of the comparator DA1, and from its output through the blocking unit on the DD3 chip to the current amplifier on transistors VT1 and VT2, the load of which is the electromagnetic relay K1. When the temperature inside the refrigerator chamber exceeds the threshold set by the variable resistor R8, a high level voltage will appear at the output of the comparator DA1, which will open the transistors VT1 and VT2. As a result, a current will flow through the turnip winding K1. it will work and its contacts K1.1 connect the compressor motor M1 to the network. The temperature in the refrigerator will start to decrease, and the resistance of the thermistor RK1 will increase. But as soon as the temperature drops to the threshold set by the resistor R8, taking into account the hysteresis introduced by the resistor R12, the comparator DA1 will work and a low level voltage will be set at its output. Transistors VT1 and VT2 of the current amplifier will close, the current through the winding of relay K1 will stop and its contacts K1.1 will open the power supply circuit of the compressor motor. The time-setting unit consists of a timer [2] on microcircuits DD1, DD2, an RS-trigger on elements DD4.1 and DD4.2, a current amplifier on transistors VT3, VT4 and an electromagnetic relay K2 that controls the operation of the heating element of the freezer thawer. The DD1 chip performs the functions of a master oscillator and a frequency divider for 32768 and 60, and the DD2 chip acts as a frequency divider counter by 6. When the power is turned on, the voltage supplied to the R inputs of the DD1 chip through the C1R3 reset circuit will set it to zero. Accordingly, the supply voltage passed to the input of the DD4.2 RS flip-flop element through the C6R16 reset circuit will put it in a single state. As a result, at the output 4 of the element DD4.2 and at the input 2 of the element DD4.1, the voltage will be low, and at the output 3 of the element DD4.1 - high. The latter will go to the reset input R of the counter-divider DD2 and reset it. The master oscillator of the DD1 microcircuit generates a pulsed voltage, the frequency of which is set by the variable resistor R11 in the range of 175...280 Hz. The period of this voltage in the middle position of the slider of the resistor R1 1 is approximately 4,6 ms. In the DD1 microcircuit, the pulses of its master oscillator are fed to a frequency divider, which increases the period of the pulse voltage by 32768 times, and a signal with an oscillation period of 1 minutes appears at the output S2,5. Next, the signal is applied to input C of the DD1 microcircuit, and its frequency is divided by another 60. so that the period of the pulse voltage at the output M of the DD1 microcircuit will already be 2,5 hours. The first positive voltage drop that appears at the output M of the DD1 microcircuit is approximately 1,5 .4 h, passes through the differentiating chain C13R1 to the input 4.1 of the DD3 RS flip-flop. The trigger will switch and the voltage at the output of element 4.1 DD4.2 will change from high to low. As a result, a high level voltage will be established at the output of the DD4.1 element and, accordingly, at the input of the DD3 element. It will open transistors VT4, VT2, a current will flow through the coil of relay K2.1, the relay will work and by closing contacts KXNUMX will connect the heating element of the Rh defroster to the mains. At the same time, the low-level voltage from the output of the DD4.1 element will go to the enable input C of the switch on the DD3 chip. The switch will close and disconnect the thermostat from the current amplifier. The same low-level voltage applied to the R input of the DD2 microcircuit allows the divider to work by 6. As a result, the signal from the S1 output of the DD1 microcircuit, which is fed to the CP input of the DD2 microcircuit, will cause a high signal to appear at its output 15 (pin 6) after 5 minutes. level. This voltage will go to the input 6 of the element DD4.2 RS-flip-flop. The trigger will switch, and a low-level voltage will appear at the output (pin 4) of the DD4.2 element, which will close the transistors VT3 and VT4. The passage of current through the relay K2 will stop, and its contacts K2.1 will disconnect the heating element of the defroster from the mains. The signal coming to the enable input from the DD3 chip will open the switch, and the thermostat will be connected to the current amplifier. The dividers on the DDT and DD2 microcircuits will be in zero, and the RS flip-flop will be in a single state. With the arrival of the next pulse from the output M of the DD1 microcircuit, after 2,5 hours the defroster will turn on again for a time equal to 15 minutes. The power supply unit for the temperature control device of the refrigerator consists of a transformer T1, a bridge rectifier on diodes VD4 - VQ7. voltage regulator on the DA2 chip and smoothing capacitors C7 - C9. The output voltage of the power supply is +9 V. All elements of the device, except for the transformer T1, are mounted on a printed circuit board made of one-sided foil fiberglass 1,5 mm thick and 110x65 mm in size (Fig. 2).

For installation, fixed resistors MLT-0,125, variables (R8 and R11) -SP4-1, thermistor RK1 - MMT-1 were used. Capacitors C8 and C9 - K50-16, C1-C7 - K73-9. Transistors KT315G (VT1, VT3) can be replaced by KT3102A, and KT815A (VT2, VT4) - by KT817A. Electromagnetic relays - automotive 113.3747-10 [3], their powerful contacts withstand the inclusion of the refrigerator compressor electric motor. Transformer T1 with a power of 2 ... 4 W - from the network adapter [4]. When adjusting, the control device is disconnected from the refrigerator, and table lamps are connected instead of the compressor motor and the heating element of the defroster. The temperature control unit operates when the temperature changes from -14 to +4 ° C, therefore, for the time of its establishment, it is recommended to reduce the resistance of the resistor R8 to 1,5 kOhm, and close R7 with a jumper. In this case, the temperature controller will operate at temperatures from +18°С to +40°С, which are easy to ensure during adjustment. To speed up the verification of the operation of the timing unit, it is recommended to reduce the capacitance of the capacitor C2 by 100 times. then the period of the pulse voltage at the output M of the DD1 chip will be reduced to 90 s. A checked and adjusted device can be installed in a refrigerator, while not forgetting to increase the ratings of the elements R8, C2 to those indicated in the diagram. The DD3 microcircuit can be excluded if the output of the resistor R15, right according to the diagram, is connected to the base of the transistor VT1 and the point of their connection through the KD503A diode is connected to output 3 DD4.1 (the diode cathode is connected to this output). Literature

Author: G.Skobelev, Kurgan

Machine for thinning flowers in gardens

02.05.2024 Advanced Infrared Microscope

02.05.2024 Air trap for insects

01.05.2024

▪ Sony A7R IV Full Frame Mirrorless Camera ▪ Miniature 868MHz radio module with built-in antenna

▪ section of the site Radio - for beginners. Article selection ▪ article by Daidoji Yuzan. Famous aphorisms ▪ article Who is John Calvin? Detailed answer ▪ article Abdominal pain. Health care ▪ article Flash control device. Encyclopedia of radio electronics and electrical engineering

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

Leave your comment on this article:

Leave your comment on this article: