|

|

ENCYCLOPEDIA OF RADIO ELECTRONICS AND ELECTRICAL ENGINEERING

Installation of open wiring. Encyclopedia of radio electronics and electrical engineering

Encyclopedia of radio electronics and electrical engineering / Electric installation work Open wiring is laid on the surfaces of walls and ceilings, therefore, its installation can only begin when all finishing work has been completed, including painting or wallpapering. Installation of electrical wiring on rollers and clips On combustible surfaces, for example, on wooden bases, it is allowed to lay wires when they are mounted on rollers and special plastic clips (Fig. 30).

The rollers are attached to the bases with round head screws. In order not to split the porcelain roller when fastening with nails, an elastic washer must be placed under the nail head. When laying wires in dry or damp rooms, RSh-4, RP-2,5, RP-6 rollers are used. Only rollers of the RSSH-4, RSV-4 type are suitable for damp rooms. The distance between adjacent rollers located along the electrical wiring route should not exceed 80 cm, and between the rollers in a row - 3,5 cm. The wires are attached to the rollers as follows. One end of the wire is fixed on the first roller, then the wire is pulled along the installation line of the rollers, marking the places of branches on it. After that, the wire is removed, the branch wires are attached to it and finally pulled. The wires are fixed first on the end rollers of the straight sections of the route, then on the middle roller and finally fixed on all intermediate rollers. When installing the roller, a metal strip 10 mm wide is placed under the screw head. As a metal strip, galvanized or anti-corrosion-coated sheet metal is used. A pad of 14 mm wide electric cardboard is placed on a metal strip. The wire is laid flat on the gasket, after which the ends of the metal strip, together with the cardboard gasket, are bent and fastened with a buckle or wire loop. Fastening on rollers of wires of the APN, APPVS, PPVS brands without a separating film between the cores is shown in fig. 31.

Methods for fixing wires on rollers are shown in fig. 32.

The scheme of laying single-core wires of the APR, APPV, APRV, APN brands in the room is shown in fig. 33, all distances are given in mm.

If wires without a separating film are used, for example, APN, APPVS, PPVS brands, then at the points of their attachment, a longitudinal cut is made along the insulation between the wires so as not to damage the insulation, put the wire on the roller head and tie it to the rollers with a braid or thin twine. Twisted two-core wires of the brand PRD, PRHD are laid on the rollers. They are fixed first on the extreme rollers, then on the middle one and on all the others. The wires are tied only on the extreme rollers, while they are only put on the intermediate ones. The wires are fixed on the rollers with cotton braid or thin twine. In the corners of the room, rollers are installed from the ceilings and adjacent walls at a distance of 1,5-2 roller heights. End rollers are installed at the same distance from the passages through the walls. When laying wires from a dry room to a damp one, from a damp room to another damp one, and when laying wires from rooms to the outside, each wire is laid in a separate insulating tube (Fig. 34). When laying wires from a damp room to a damp funnel, it is necessary to fill in on both sides of the passage with an insulating compound.

When installing wires when passing them from one dry room to another dry room, all wires can be laid in one insulating tube. When passing through the wall, both to the extreme rollers and to the end wires, they are tied on one side and the other with a cross with a clamp with soft steel wire (preferably galvanized) with a diameter of 0,6-0,8 mm. At the points of attachment to the roller, the wires are wrapped in two layers of rubberized or PVC insulating tape to prevent damage to their insulation. The wires are tied to the intermediate rollers with a cross, and to the corner ones - with a cross with a clamp. Fastening of wires to rollers by means of PVC rings is possible. The rings are cut from a PVC tube with a diameter of 40 mm and a wall thickness of 1,5-2 mm. With this method of fastening, winding the insulating tape on the wire is not required. Installation of electrical wiring when attaching wires and cables with a metal strip and staples Installation of wires and cables of the ANRG, AVRG, APVG, AVVG, AVP, ABB brands on wooden and brick bases is carried out using a metal strip, as shown in fig. 35, a, b or with the help of a strip smeared into the base (Fig. 35, c).

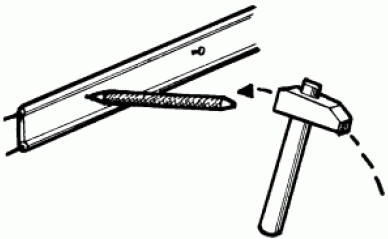

Fastening is performed as follows. Previously, strips of at least 10 mm wide and 0,3-1 mm thick are cut from tinplate, galvanized or painted steel sheets. The length of the strip is taken depending on the brand of the cable and its cross section - it can be 120-200 mm. A strip is nailed to the base along the marked wiring route and the cable being fixed is wrapped around it. On concrete and brick bases, the strip is nailed with a dowel-nail. For manual hammering, a dowel-nail of the type DGR 3,5 x 25 mm and DGR 3,5 x 35 mm is used. If corrugated dowels are used such as DG 4,5 x 30 mm, DG 5,5 x 35 mm, DG 6,8 x 35 mm, then a special gun is used to drive them. On wooden bases, the strip is nailed with nails with a diameter of 1,6 mm, a length of 40-50 mm. When fastening wires with strips, strip buckles of the K395, K398 type are used, which are fixed with a K407 buckle. When attaching wires with a strip embedded in the base, sockets are drilled or hollowed out along the marked route. The diameter of the drill, punch or drill should be 10 mm, the depth of the socket should be 30-40 mm. The strip is smeared into the nest with an alabaster solution. The wires are fixed in a strip with a buckle or in a lock. The length of the strip attached to the lock should be 10 mm longer than the length of the strip attached to the buckle. The wires are protected by pads made of electric cardboard, which are placed between the strip and the wire. The electric cardboard should protrude from both sides of the strip by 1,5-2 mm. The distance between the strips should be 50 cm, and between the strips embedded in the base - 40 cm. Wires and cables are attached to brick, concrete and wooden bases with one-leg or two-leg brackets. On brick and concrete bases, the brackets are fixed with nylon dowels with screws, on wooden bases - with screws. To fix the bracket with a nylon expansion dowel, you must first mark the electrical wiring route, then drill along the route at the base of the sockets recesses with a diameter of 8 mm, a depth of 35 mm, insert the dowel into the socket by hand pressing or lightly hitting with a hammer. Then the screw is passed into the hole of the bracket, inserted into the dowel and wrapped with a screwdriver. When fastening horizontal cables along the walls with brackets with one tab, the latter should be located below the cable. When laying cables along walls and ceilings, as well as at corners and ends, they are fixed with brackets with two legs. The distance between the brackets should not exceed 50 cm. It is allowed to fasten cables during vertical laying with brackets with one tab on either side of the cable if there is a stiffening rib on the bracket. Outdoor installation of electrical wiring on wooden bases Flat wires and cables sheathed from slow-burning or non-combustible materials, such as APPR wires, can be laid directly on combustible bases with nail fastening. Nails should be 1,4-1,6 mm in diameter, 25-32 mm long, with caps up to 3 mm in diameter. They must be hammered along the middle line of the separating film between the cores. They hammer nails with a hammer weighing up to 200 g using a mandrel that protects the wires from damage during operation (Fig. 36).

It is recommended to put ebonite, plastic or rubber washers under the nail heads (for flat wires). Four-core wires are fastened with strips cut from tinplate, galvanized or painted steel sheets. Strip width - no more than 10 mm, thickness - 0,3-1 mm, length - 80 mm. Under the metal strips, it is necessary to place spacers made of insulating cardboard so that they protrude 1,5-2 mm from both sides of the strip. If there is no electrical insulating cardboard, any cardboard with a thickness of 0,3-0,5 mm can be used. Under open wires of grades APV, APPV, APN, APRV, laid on combustible bases, it is necessary to put a layer of sheet asbestos with a thickness of at least 3 mm. It should protrude from each side of the wire by at least 10 mm. Metal strips are used to secure the wires. When attaching wires in strips, the latter are fixed with a K-407 buckle or in a lock. The length of the strip attached to the lock must be 10 mm longer than the length of the strip for the buckle. Under the metal strips, the wires should be protected with insulating cardboard pads protruding 1,5-2 mm on both sides of the strip. On fig. 37 shows the open laying of electrical wiring in the room directly on wooden bases.

Installation of electrical wiring in steel and plastic pipes In steel pipes, electrical wiring can be performed openly on the surface, hidden, with external wiring, as well as when entering the building and installing electrical wiring in the attic. Before proceeding with the installation of electrical wiring, steel pipes should be cleaned of rust and deburred in the end part so as not to damage the wires when they are pulled into the pipe. To protect against corrosion, pipes must be painted or coated with bituminous varnish both outside and inside. Galvanized pipes should not be painted. When laying pipes in concrete, they are not painted on the outside. Pipes should be bent on special equipment so as not to crush them at the corners. The bending angles must be 90°. When laying hidden pipes, the bending radius must be at least six outer diameters of the pipe, with open laying - at least four, and when laying in concrete - at least ten. To carry out curved sections of the electrical wiring route, as well as to enter wires into the body of the electrical installation, flexible inputs of the K1080-K1088 type are used. The inlets consist of a polymer-coated metal hose, inlet and pipe couplings. To connect pipes to each other, couplings of the TR, MT type are used. The coupling is made with metal hoses or branch pipes. The connection with couplings is made without thread. Inlet branch pipes of the U476-U479 type are used for inserting steel pipes of electrical wiring and metal hoses into the metal cases of electrical installations. To ensure proper grounding contact between the body of the electrical installation and the pipes, adjusting grounding nuts of the K480-K486 type are used. For fastening steel pipes of electrical wiring to various metal structures, clamps of the C437-C442 type and NT type linings are used. For fastening steel pipes of electrical wiring, as well as wires and cables to various bases, brackets of the K142-K470 type are used. They are attached to the bases with bolts, screws, screws. Before tightening the wires, a steel wire or cable with a diameter of 3-4 mm is laid in the pipes. The ends of the wires are attached to a cable or steel wire and with their help the wire is pulled inside the pipe. Steel pipes of electrical wiring can be used as grounding or neutral conductors, if proper electrical contact is ensured throughout them. It is possible to lay wires of APV, APRTO, APRV, APR, APPVS, APPV, APN brands in plastic pipes. Polyethylene pipes can only be used for hidden electrical wiring on fireproof grounds instead of steel pipes. Viniplast pipes should be used for hidden and open electrical wiring instead of steel pipes as a protective sheath against mechanical damage. Threading on vinyl plastic pipes is not allowed. You can only do rolling. The depth of the furrows, as well as the nests in them for the installation of branching and broaching boxes, recessed installation products, must be determined taking into account the thickness of the plaster or facing layer. Viniplast and polyethylene pipes should be laid below heating or hot water pipes. When crossing vinyl and polyethylene pipes with steel heating pipes, the distance between them must be at least 5 cm. Avoiding obstacles in horizontal sections of pipe laying should not create the possibility of moisture accumulation ("water bags"). Plastic pipes must be connected to each other by couplings of the type U438-U442, U297, U276-U279 from the same material as the pipes. The ends of the pipes must fit snugly together and be in the middle of the coupling. Connection and branching of wires should be carried out in boxes or boxes. Connection of wires directly in the pipe is not allowed. The inner diameter of plastic pipes when laying several wires in them must correspond to the number and diameter of the wires being laid and be at least 11 mm. The bending radii of plastic pipes must be at least ten times the diameter of the pipe when laying pipes in concrete masses (as an exception, six times the radius is allowed). To ensure free pulling of wires into pipes, as well as in case of need to replace them, the distance between pull-through or junction boxes should not exceed 10 m on a straight section of the route, 7,5 m - on a section of a route with one corner, 5 m - on a section of the route with two or three corners. Plastic pipes that are not inserted into boxes and cases of apparatus and instruments must be terminated with insulating bushings of the U292, U293 type or funnels. Hidden laying of electrical wires in vinyl plastic pipes along combustible walls (wooden), ceilings and structures is allowed provided that the pipes are laid on a layer of sheet asbestos with a thickness of at least 3 mm or a layer of plaster with a thickness of at least 5 mm, protruding from each side of the pipe by at least 5 mm, followed by plastering the pipe with a layer of at least 10 mm thick. Viniplast pipes can be laid on combustible bases covered with wet plaster with a layer of at least 20 mm thick. Plastic pipes are attached to structures and various bases with brackets such as SD-311, SO-27, KS, KSP. Staples of the KS and KSP types are used for open wiring. Author: Korshevr N.G.

Traffic noise delays the growth of chicks

06.05.2024 Wireless speaker Samsung Music Frame HW-LS60D

06.05.2024 A New Way to Control and Manipulate Optical Signals

05.05.2024

▪ Molecular machines will provide a breakthrough in medicine ▪ SEAGATE will automatically encrypt all contents of your hard drive ▪ Environmentally friendly cooling agent ▪ The crowd has a collective mind ▪ Microsoft will decipher the human immune system

▪ section of the site Fundamentals of safe life (OBZhD). Article selection ▪ article Libation to Bacchus. Popular expression ▪ Which countries did Alexander the Great conquer? Detailed answer ▪ article Certification of the organization of work on labor protection ▪ article Power supply. Directory

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

Leave your comment on this article:

Leave your comment on this article: