|

|

BUILDER, HOUSEHOLDER

Country house with all amenities. Tips for the home master

Directory / Builder, home master When it comes to building a country house, it almost always means that all the "amenities" will be equipped in the yard. Among them there is a shower (bathroom), and a toilet, and a bathhouse, and a washbasin ... And this means that in any, even the most vile weather, you will have to, cursing everything in the world, make your way to such "amenities". And only in very rare cases, during the construction of a house, completely "urban" common areas are included in its project. An obstacle to the civilized arrangement of common areas is the lack of a centralized sewage system. However, at almost any site, it is possible to organize the neutralization of domestic wastewater, including fecal waste, with their subsequent full or partial use or removal outside the site. Well, a manor house with a sewerage system can be equipped with the most modern sanitary equipment. In a country house, the sanitary and hygienic complex can be much more complete than in a standard city apartment. In addition to a toilet, a bathroom with a washbasin and a kitchen sink, one more toilet with a washbasin, a bathroom-laundry room, a washroom with a bidet, a washroom near the garage or workshop, as well as a bathhouse or sauna can be equipped here. So, let's start with the most important thing - the removal and disposal of domestic wastewater. For this, facilities are mainly used of two types: cesspools with periodic removal of accumulated waste and local treatment facilities, when passing through which wastewater is neutralized by sedimentation and biological treatment. Depending on the specific conditions, various options for arranging local sewage using both cesspools and treatment facilities are possible. At the same time, it is advisable to make cesspools if there are sewage trucks or with a limited amount of wastewater, when it is possible to dispose of them within the backyard. The cesspool is an underground container (usually reinforced concrete) with sealed walls and a bottom. In heaving soils, cesspools are designed taking into account the forces of frost heaving: their depth is not higher than the level of soil freezing, the outer walls are erected with an inward slope, the wall and bottom reinforcement must have a rigid connection. If the groundwater level is located above the bottom of the tank, it is necessary to isolate the latter with a roofing material, pasting over the walls of the structure with it. So that the contents of the cesspool do not freeze, it is advisable to lay a heater over the ceiling: slag, expanded clay or foam plastic with clay protection from moisture and rolled waterproofing. The most convenient form of a cesspool is cylindrical. Such a container well resists lateral pressure in the soil, and its construction is relatively inexpensive - less concrete is required than for a cesspool of a different shape. With a tank diameter of 2 ... 2,5 m, the wall thickness is 80 ... 120 mm, with a larger diameter - up to 150 mm. The volume of the underground tank should be at least 10 m3, and this is not so much. If only a kitchen sink and a flush toilet are installed in your home, this volume will be filled in just a month. The easiest way, of course, is to build a container from ready-made or independently cast reinforced concrete rings. If there is a need for a large-capacity cesspool, it is not worth building a large-diameter concrete tank; it is easier to make several ordinary tanks connected by water-air bypass pipes. In addition, each compartment must be equipped with an inspection hatch. Ventilation of the cesspool is desirable to provide through the house smoke ventilation unit. Of course, by constructing a cesspool, you make the reliability of the functioning of sanitary equipment dependent on cleaning services. Sewerage with local treatment facilities has a significantly greater autonomy.

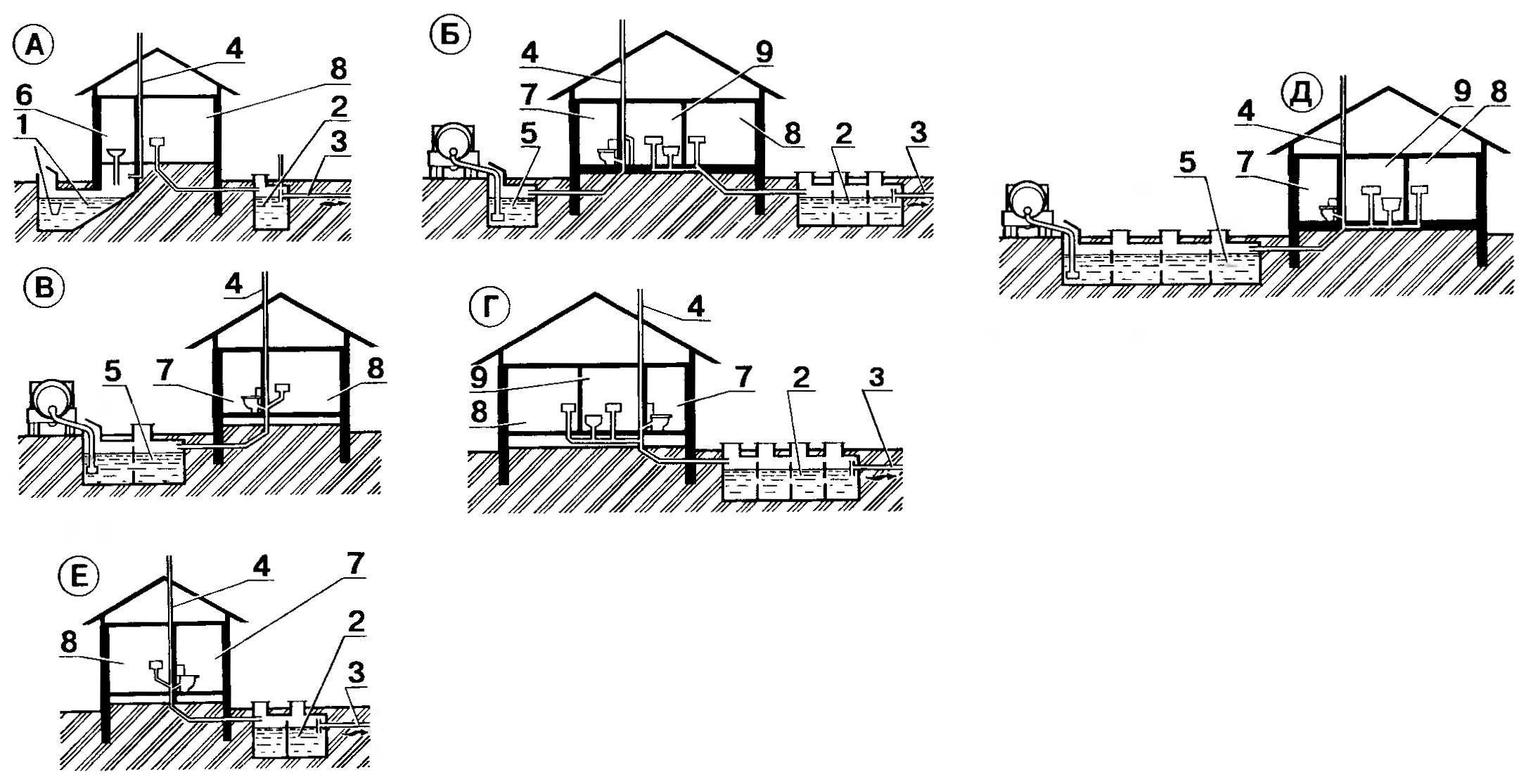

The numbers indicate: 1 - backlash closet cesspool, 2 - septic tank, 3 - outlet to treatment facilities, 4 - ventilation riser, 5 - domestic wastewater cesspool, 6 - backlash closet, 7 - water closet, 8 - kitchen with sink, 9 - bathroom with bathtub and washbasin.

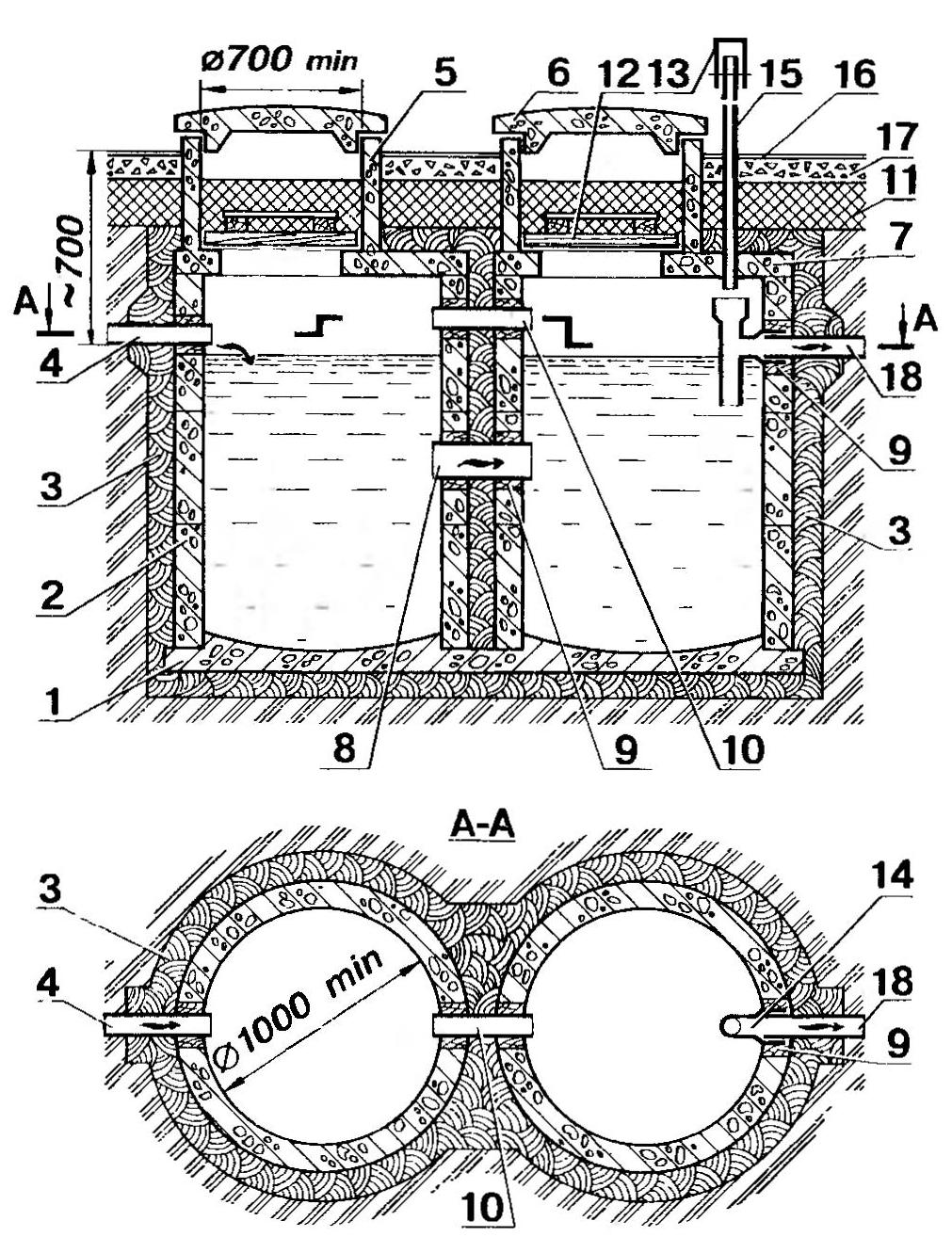

The numbers indicate: 1 - filter material (broken brick, crushed stone, slag or coarse sand), 2 - manhole cover (reinforced concrete), 3 - ventilation riser, 4 - well wall (asbestos-cement or reinforced concrete pipe), 5 - supply channel, 6 - blind area, 7 - crushed stone backfill, 8 - insulation (clay), 9 - insulation, 10 - ring (reinforced concrete), 11 - hole for passing the filtrate, 12 - bottom (reinforced concrete), 13 - ceiling (reinforced concrete), 14 - manhole cover (wood), 15 - support ring (monolithic concrete).

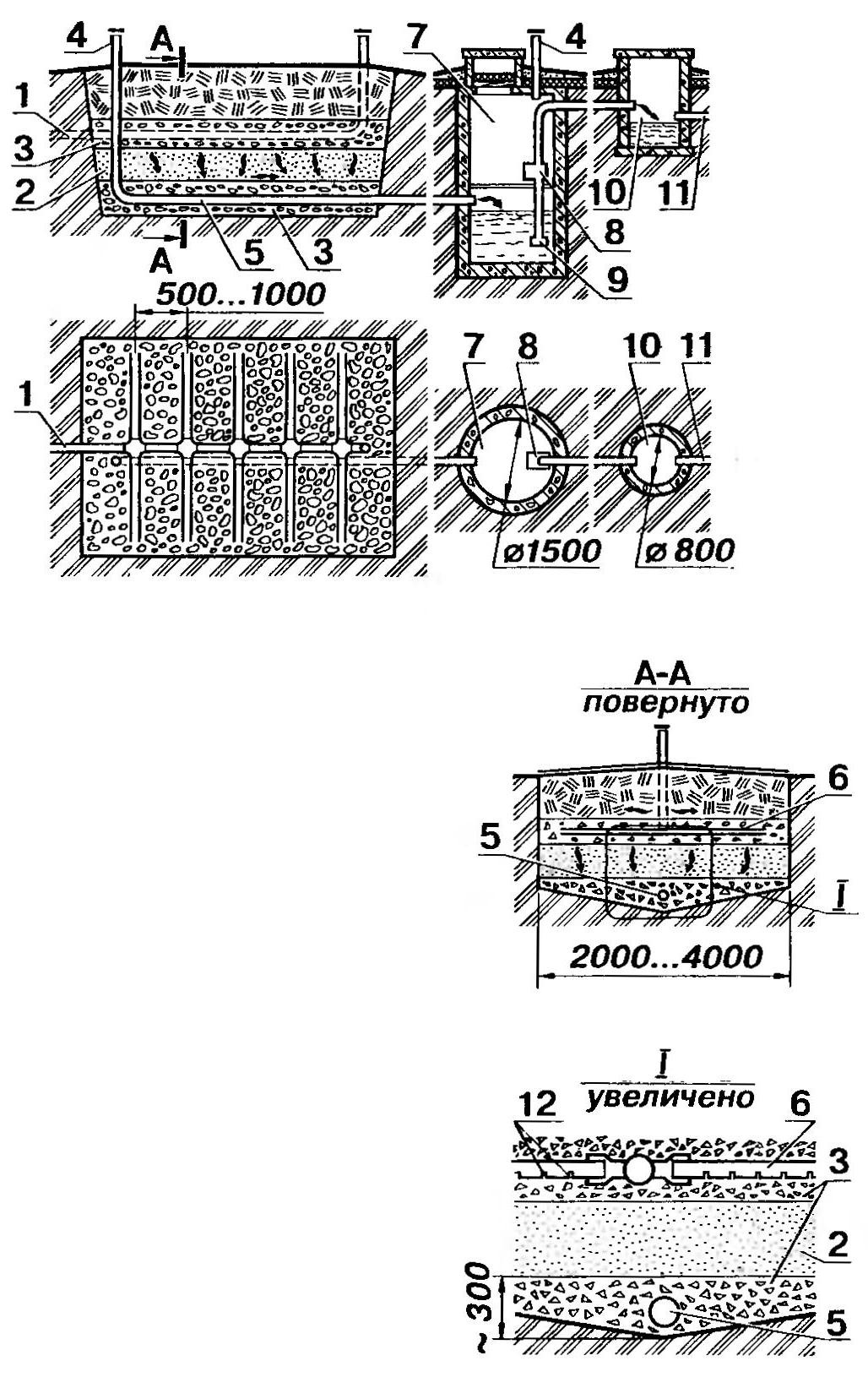

The pollution of domestic wastewater is determined mainly by the presence of organic substances in them, which must be mineralized during the treatment process. This is usually done in two stages: first, wastewater enters special settling tanks (septic tanks), where they are stratified and clarified, and then subjected to further processing at biological treatment facilities. A septic tank is a sealed container through which domestic wastewater passes at a low rate (for four or more days). Suspended substances precipitate, and clarified water is sent for subsequent biological treatment. The organic part of the sediment is destroyed in six to twelve months under the influence of anaerobic microorganisms and turns into gaseous and soluble minerals. To improve the cleaning process, the septic tank is divided into several separate chambers connected by pipes. The size of the septic tank is chosen in such a way that its internal volume is 3 ... 5 times higher than the average daily volume of wastewater. For example, with a drain of 200 l / day. the volume of the septic tank must be at least 0,6 m3. A septic tank is arranged in approximately the same way as a cesspool: it is a sealed container with an inspection hatch, protected from freezing, as well as from rain and flood waters. Through the hatch, the surface of the sewage is periodically cleaned from a crust of floating silt particles and the bottom is cleaned of sludge once or twice a year. By the way, it is not recommended to remove all the silt, about 20% of this mass should be left at the bottom for the growth of bacteria that contribute to the decay of organic matter. After passing through the septic tank, the clarified wastewater enters the filtering facilities for biological treatment. This method is based on the use of the vital activity of microorganisms in the filter material. They quickly oxidize organic matter and turn it into harmless decay products. Since the vital activity of aerobic bacteria is associated with oxygen consumption, biological treatment facilities should provide the largest area of wastewater contact with air. To remove decay products that are harmful to the life of bacteria (for example, carbon dioxide), provide effective ventilation. The filtering device is selected depending on the characteristics of the soil that affect the efficiency of wastewater treatment, the volume of runoff and the size of the personal plot. The simplest and cheapest treatment plant is a filter well. It functions due to the natural ability of porous soils to pass water through itself and divert it outside the saturated area. The throughput of such a device depends on the absorbing properties of the soil located at a depth of 1 ... 3 m, and the area of \uXNUMXb\uXNUMXbcontact with wastewater. Well, the degree of biological treatment depends on the quantity and quality of the filter material put into the well instead of the extracted soil, on the surface of which silt inhabited by microorganisms is formed. Using organic residues as nutrients, microorganisms mineralize and purify wastewater that enters the well. The required area of the filtering surface is easy to calculate if you know that the water absorption of 1 m2 of sandy soils is 60...100 l/day. (sandy loam - 30 ... 50 l). For example, with a wastewater volume of 600 l / day. the working surface of sandy soils located along the perimeter of the filter material should be 6 ... 10 m2. For sandy soils, this value increases to 12 ... 20 m2. The filtering material can be crushed granite or brick, pebbles, slag, coke, peat or even sand. In the well, these materials are arranged so that its larger components are in the center, and the smaller ones are on the periphery. The design scheme of the filter well is selected depending on its throughput and the materials used. In any case, an air cavity equipped with a lid is left above the central part of the filter material. Air exchange in the cavity is carried out through the ventilation riser. In the walls of the well, holes are provided for passing the filtrate from the central part to the periphery. The height of the filter material is 1 ... 2 m, while the distance from the bottom of the well to the groundwater level must be at least 1 m. If for some reason it is not possible to build filter wells, underground filtration fields are equipped on the site. They are based on an irrigation system of perforated pipes laid in earthen trenches, through which wastewater previously cleaned in a septic tank passes. In this case, the absorption of wastewater occurs in the surface layer of soil up to 1 m deep. The estimated area of the soil through which filtration is carried out should be 2 times larger than for filtering wells. So, with a drain of 600 l / day. the total working area of trenches in sandy soils is 12...20 m2, and in sandy soils - 25...40 m2. With a filter layer thickness of 250 mm and a bottom width of 500 mm, the working surface of 1 linear meter of the trench is 1 m2, respectively, the total length of the trenches will be: for sandy soil - 12 ... 20 m, for sandy loam - 25 ... 40 m. Underground filtration fields are located, as a rule, no closer than 15 m from a residential building. Wastewater that has passed through the septic tank is sent to the distribution well, and from it through irrigation pipes - directly to the filtration fields. For the irrigation system, asbestos-cement or ceramic pipes with a diameter of about 100 mm are used, which are laid in trenches in a layer of filter material 200 ... 300 mm thick with a slope of 0,003 ... 0,005 towards the drain. To pass wastewater in the lower part of the asbestos-cement pipes, cuts are made to half their diameter with a width of 15 ... 20 mm in increments of 150 ... 200 mm, and holes are drilled in ceramic pipes. For the same purpose, pipes are laid with gaps 20 ... 30 mm wide, which are covered from above with a roofing material tape. To prevent rain and flood waters from entering the trench, after backfilling it is covered with roofing material, and a layer of soil is placed on top of it. For air inflow into the filter layer, ventilation risers with a diameter of about 100 mm and a height above the ground of 0,5 ... 1 m are installed at the ends of the distribution pipes. On loamy and clayey soils with low (practically zero) water absorption, sand and gravel filters are used. Wastewater that has passed through such treatment facilities is diverted outside the homestead plot - into a drainage ditch, ditch or ravine. A sand-gravel filter is a trench or pit filled with filter material, in the thickness of which, at horizons spaced 1 ... 1,5 m in height, irrigation and drainage networks of asbestos-cement or ceramic pipes with a diameter of about 100 mm are placed . At the level of the pipes, two layers of large-pore filter material are laid - for example, gravel, crushed stone or slag, and the space between them is filled with coarse sand. The distance between parallel rows of irrigation pipes should be 0,5 ... 1 m, the height of the sand filter should be at least 0,5 m, and the area of \u1b\u2bthe pit should be in direct proportion to the volume of wastewater. When calculating, it should be borne in mind that 60 ... 100 liters of waste fluid per day passes through 600 m6 of the horizontal surface of the sand-gravel filter. If the daily volume of wastewater is 10 liters, then a pit with an area of 2 ... XNUMX mXNUMX will be required. Due to the fact that the outlet pipe in the sand and gravel filter is located at a depth of 1,5 ... 2 m, the discharge of treated wastewater outside the backyard plot by gravity is impossible. In this case, it is necessary to direct the water that has passed through the sand and gravel filter into the surface drain using a pumping station with an electric pump, equipped, as a rule, with a small intermediate tank with a float level sensor, which allows the pump to operate automatically. Interestingly, in the summer, treated wastewater can be used to irrigate the garden. Author: I. Khoroshevsky

▪ Horizontal bar from under the bed ▪ How to heat the house with an ordinary kettle

Machine for thinning flowers in gardens

02.05.2024 Advanced Infrared Microscope

02.05.2024 Air trap for insects

01.05.2024

▪ Lenovo is the largest manufacturer of laptops ▪ 1200V CoolSiC G5 Schottky Diodes in D2PAK Dual Lead Package

▪ section of the site Power supply. Article selection ▪ article Fooling around. Popular expression ▪ article What is satire? Detailed answer ▪ Mamura's article. Legends, cultivation, methods of application ▪ article Phase indicator. Encyclopedia of radio electronics and electrical engineering ▪ article Self-shutdown power supply. Encyclopedia of radio electronics and electrical engineering

Home page | Library | Articles | Website map | Site Reviews www.diagram.com.ua |

Arabic

Arabic Bengali

Bengali Chinese

Chinese English

English French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Malay

Malay Polish

Polish Portuguese

Portuguese Spanish

Spanish Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese

See other articles Section

See other articles Section